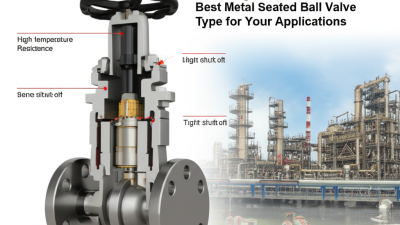

Understanding the Advantages of the Best Metal Seated Ball Valve Type for Your Applications

In the realm of fluid control technologies, the Metal Seated Ball Valve has emerged as a pivotal component for various industrial applications. According to a recent market analysis, the global ball valve market is projected to grow from $3.47 billion in 2020 to $5.08 billion by 2027, fueled by the increasing demand for durable and reliable flow control solutions. Metal Seated Ball Valves are particularly favored for their superior performance in high-pressure and high-temperature environments, making them ideal for sectors such as oil and gas, chemical processing, and power generation. Their ability to withstand abrasive and corrosive media not only enhances system reliability but also contributes to significant cost savings through reduced maintenance needs. As industries continuously seek efficient and robust valve solutions, understanding the unique advantages of Metal Seated Ball Valves becomes essential for optimizing operational efficiency and ensuring safety across various applications.

Comparative Analysis of Different Metal Seated Ball Valve Types

When choosing a metal seated ball valve for your application, it's crucial to evaluate the different types available in the market. A comparative analysis reveals that the two predominant types—floating ball valves and trunnion-mounted ball valves—offer distinct advantages tailored to specific operational requirements. According to a recent market report by Research and Markets, the global ball valve market is expected to grow by 6.4% CAGR from 2021 to 2026, with metal seated options becoming increasingly popular due to their superior performance in high-temperature and high-pressure settings.

Floating ball valves are typically favored for general applications where pressures are moderate. Their design allows the ball to "float" within the valve body, creating a tight seal against the seat when pressure is applied. Conversely, trunnion-mounted ball valves are engineered for larger, high-pressure applications, providing exceptional stability and reduced torque, which can lead to significant operational efficiency. The same market report highlights that trunnion-mounted valves are expected to capture a substantial market share—around 35%—due to their reliability in critical infrastructure sectors such as oil and gas, where operational failures can have severe repercussions.

Ultimately, the choice between these metal seated ball valve types should be aligned with the specific needs and conditions of your application, considering factors such as pressure, temperature, and medium compatibility to ensure optimal functionality and performance.

Key Features and Benefits of Each Metal Seated Ball Valve Type

When selecting a metal seated ball valve for various industrial applications, it’s essential to understand the key features and benefits that distinguish each type. Metal seated ball valves are favored for their durability and ability to withstand high temperatures and pressures, making them suitable for rigorous environments. One significant advantage is their resilience to wear and tear, which results in a longer lifespan compared to traditional soft-seated valves. This durability leads to lower maintenance costs and increased reliability in operations, particularly in sectors like oil and gas, water treatment, and manufacturing.

In addition, the specific design features of each metal seated ball valve type contribute to their functionality. For instance, some models are designed with advanced sealing technologies that enhance performance under extreme conditions, while others offer flexibility in terms of installation and operation, catering to diverse system requirements. The ongoing trends in valve technology, influenced by market demands, emphasize efficiency and compatibility with automation systems. As industries continue to evolve, understanding these features ensures that businesses can optimize their systems, ultimately improving overall efficiency and safety within their operations.

Performance Metrics: How Metal Seated Ball Valves Stack Against Each Other

When it comes to industrial applications, the choice of valve can significantly impact operational efficiency and longevity. Metal seated ball valves are gaining attention for their robust construction and versatility. Evaluating their performance metrics is essential to understand how they compare against other valve types. Factors such as temperature tolerance, pressure handling, and sealing capability are crucial in determining the right valve for a given application.

Tips: Always consider the specific conditions under which the valve will operate. For instance, high-temperature environments may require valves with certain alloys that resist deformation. Additionally, assess the medium being controlled, as abrasive materials can wear down softer seated options quicker than metal seated valves, ensuring minimal downtime.

Another critical metric is the valve's maintenance needs. Metal seated ball valves often require less frequent maintenance, thanks to their sturdy design. Investing in high-quality components might seem costly initially, but the reduction in operational interruptions can lead to significant savings over time. Tips: Regular inspections complemented by expert evaluations can help identify any wear and tear early, thus extending the operational life of your valves.

Performance Metrics of Metal Seated Ball Valves

Cost Considerations: Evaluating Value Across Various Metal Seated Ball Valves

When selecting the best metal seated ball valve for your applications, cost considerations are paramount in evaluating the overall value. Metal seated ball valves, known for their durability and ability to handle high-pressure systems, can vary significantly in price depending on the materials used, manufacturing processes, and specific design features. It's essential to analyze not only the upfront costs but also the long-term benefits these valves can bring to your operation.

Tip 1: Consider the total cost of ownership rather than just the purchase price. Factors such as maintenance, downtime, and operational efficiency can dramatically affect the overall value of your investment. A slightly higher initial expenditure might lead to substantial savings over the valve's lifespan if it requires less maintenance and offers superior performance.

Tip 2: Don’t overlook the importance of working closely with reputable suppliers who can guide you through the selection process. They can help you assess the specific requirements of your application to ensure you choose a valve that balances performance with cost-effectiveness tailored to your needs.

Application Suitability: Choosing the Right Metal Seated Ball Valve for Your Needs

When selecting a metal seated ball valve for your specific application, it’s crucial to consider various factors that influence performance and reliability. Metal seated ball valves are known for their durability and ability to handle extreme temperatures and pressures, making them ideal for industrial applications. Whether dealing with corrosive fluids or maintaining a consistent flow in high-demand environments, choosing the right type ensures that your operations run smoothly and efficiently.

In addition to the operational characteristics, understanding the environmental conditions in which the valve will be used is equally important. For instance, if you require a valve that can withstand outdoor conditions, you’ll want to ensure it's resistant to rust and corrosion while maintaining performance standards. Just as the best outdoor faucet is designed to resist the elements and offer practical solutions, a suitable metal seated ball valve should align with your specific operational needs, ensuring longevity and functionality in challenging environments. Consideration of these aspects will lead to optimal performance and reduced maintenance costs over time.

Understanding the Advantages of the Best Metal Seated Ball Valve Type for Your Applications

| Application | Temperature Range (°C) | Pressure Rating (bar) | Material | Advantages |

|---|---|---|---|---|

| Oil and Gas | -50 to 250 | 100 | Stainless Steel | High durability and corrosion resistance |

| Chemical Processing | -40 to 180 | 50 | Alloy Steel | Excellent sealing capabilities, resistant to aggressive chemicals |

| Power Generation | -30 to 400 | 150 | Carbon Steel | High temperature and pressure resistance, suitable for steam applications |

| Water Treatment | 0 to 100 | 25 | Bronze | Good flow control, minimal maintenance required |