Understanding the Advantages of High Temperature Ball Valves in Industrial Applications

In the realm of industrial applications, the demand for reliable and efficient control systems has led to the increasing adoption of High Temperature Ball Valves. According to a report by MarketsandMarkets, the global industrial valve market is projected to reach USD 125.7 billion by 2025, with high-performance valves, particularly those capable of withstanding extreme temperatures, playing a crucial role in this growth.

High Temperature Ball Valves are designed specifically to function optimally in harsh environments, handling temperatures exceeding 450°F (232°C) while maintaining integrity and reliability. Their robust construction not only ensures safety and efficiency in processes such as oil and gas, power generation, and chemical manufacturing but also minimizes the risk of leaks and failures.

As industries seek to enhance operational performance and comply with stringent regulations, understanding the advantages of High Temperature Ball Valves becomes essential for achieving long-term success in today's competitive marketplace.

Exploring the Design Features of High Temperature Ball Valves for Industrial Use

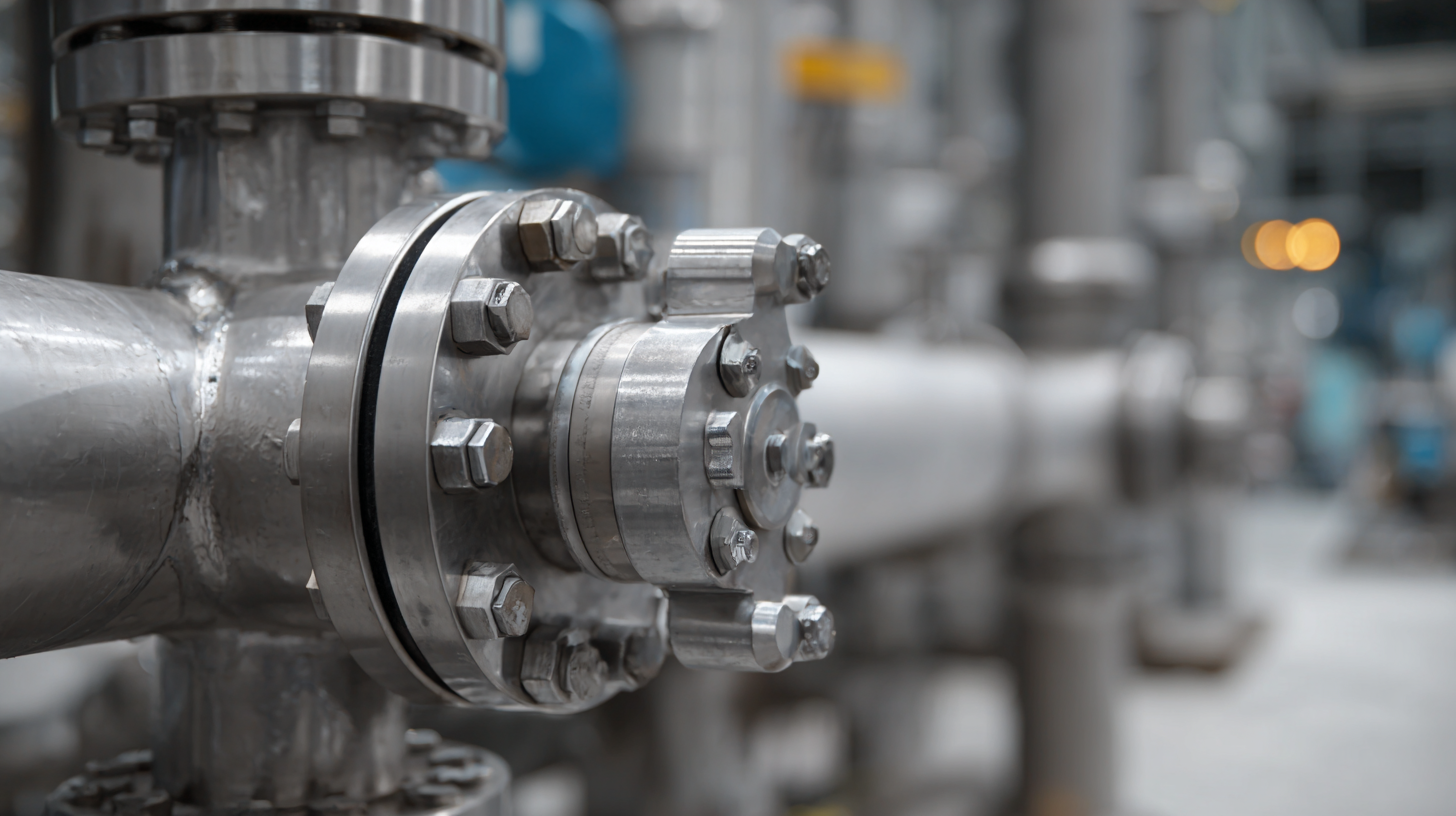

High temperature ball valves are essential components in various industrial applications, designed specifically to withstand extreme temperatures and pressures. One of the key design features that set these valves apart is the selection of materials. Typically, manufacturers utilize robust materials like stainless steel or specialized alloys to ensure durability and resistance to thermal expansion and corrosive environments. These materials not only contribute to the longevity of the valve but also minimize the risk of failure under high-stress conditions.

High temperature ball valves are essential components in various industrial applications, designed specifically to withstand extreme temperatures and pressures. One of the key design features that set these valves apart is the selection of materials. Typically, manufacturers utilize robust materials like stainless steel or specialized alloys to ensure durability and resistance to thermal expansion and corrosive environments. These materials not only contribute to the longevity of the valve but also minimize the risk of failure under high-stress conditions.

Another notable design aspect is the sealing mechanism. High temperature ball valves often employ advanced sealing technologies such as PTFE or graphite, which can maintain integrity and performance even at elevated temperatures. This is crucial in preventing leaks and ensuring consistent operation within industrial processes. Additionally, the construction of the valve body is engineered to promote smooth flow and reduce turbulence, which enhances overall efficiency. The combination of these features ensures that high temperature ball valves provide reliable performance and safety, making them indispensable in industries such as oil and gas, chemical processing, and power generation.

Key Materials and Construction Techniques in High Temperature Ball Valves

High temperature ball valves are essential components in industrial applications where temperature resistance and reliability are critical. The construction of these valves involves specialized materials designed to withstand extreme conditions. Common materials include high-performance alloys such as stainless steel, which offers excellent corrosion resistance and strength at elevated temperatures.

Additionally, materials like Inconel and Monel are often used for their ability to endure high stress and resist oxidization, making them ideal for severe service environments.

Beyond material selection, the construction techniques employed in high temperature ball valves are crucial for their performance. Advanced manufacturing processes, such as precision machining and welding, ensure tight tolerances and robust structural integrity. The use of advanced sealing technologies, such as PTFE or graphite, provides superior sealing capabilities under high temperatures and pressures.

Furthermore, rigorous quality control measures are implemented throughout the production process to guarantee that each valve meets strict industry standards and can perform reliably in demanding conditions.

Together, these materials and construction techniques contribute to the overall efficiency and durability of high-temperature ball valves in various industrial sectors.

Advantages of High Temperature Ball Valves Compared to Traditional Valve Types

High temperature ball valves offer several advantages over traditional valve types, especially in industrial applications that require resilience under extreme conditions. One significant advantage is their ability to handle higher pressures and temperatures without compromising performance. Unlike traditional gate or globe valves, which may warp or fail under such extremes, high temperature ball valves maintain their integrity and sealing capabilities, ensuring efficient operation in critical environments.

Another noteworthy benefit is their quick operation. High temperature ball valves typically feature a quarter-turn mechanism, allowing for rapid opening and closing. This can be crucial in processes where time is of the essence, such as in emergency situations or rapid cycling operations.

Tips: When selecting high temperature ball valves, consider the specific temperature and pressure ratings required for your application. Additionally, check for compatibility with the fluids being handled to ensure optimal performance and longevity. Regular maintenance is also essential to prevent failure, particularly in high-stakes environments.

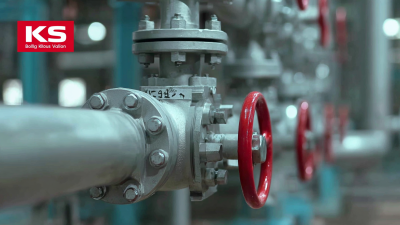

Optimal Applications and Industries for High Temperature Ball Valves

High temperature ball valves are critical components in various industrial applications, particularly in sectors that necessitate the handling of aggressive fluids at elevated temperatures. Industries such as oil and gas, chemical manufacturing, and power generation benefit significantly from the reliability and efficiency that these valves offer. According to a report by Industry Research, the global ball valve market is projected to reach approximately $15 billion by 2025, with high temperature variants accounting for a substantial portion due to their unique advantages in preventing leakage and maintaining flow control under extreme conditions.

Moreover, the aerospace and petrochemical industries are increasingly utilizing high temperature ball valves to enhance safety and operational reliability. For instance, in petrochemical production, these valves can operate up to 600°F, allowing for seamless flow control in processes such as refining and separating hydrocarbons. A study from Grand View Research highlights that the demand for high temperature valves in chemical processing is expected to grow at a CAGR of over 5% from 2020 to 2027, indicating a robust market trend driven by the need for durable and efficient flow control solutions in high-stress environments.

Best Practices for Maintaining High Temperature Ball Valves in Industrial Settings

High temperature ball valves are essential in various industrial applications, where they regulate flow and withstand extreme conditions. Proper maintenance of these valves is crucial to ensure their longevity and efficiency. One of the best practices is to perform routine inspections. Regularly check for any signs of wear or leakage, and ensure that all moving parts are functioning smoothly. Pay particular attention to the seals and gaskets, as these components are often the first to degrade under high temperatures.

Tips: Always use high-quality lubricants designed for high-temperature conditions. Lubrication helps reduce friction and wear, enhancing the valve’s operational life. Additionally, consider calibrating the valve regularly to guarantee it maintains precise flow control. Keeping records of maintenance checks and any replacements can also streamline any future inspections or servicing needs.

Another vital aspect is ensuring that the valves are installed correctly. Proper installation minimizes stress and helps maintain optimal performance. Avoid using excessive force during installation, and utilize compatible fittings to prevent damage. Make sure to train personnel on the specific requirements for the high temperature ball valves in your systems to promote effective maintenance practices.

Related Posts

-

Finding Quality Suppliers for Best High Temperature Ball Valves: The Ultimate Guide to Ensuring Durability and Performance

-

How to Choose the Right High Temperature Ball Valve for Your Industry Needs

-

7 Essential Benefits of Choosing Valve Ball Valves for Your Piping Systems

-

Exploring Future Trends in Best Way Ball Valve After Sales Service and Maintenance Cost Efficiency

-

Real World Applications of Best Ball Valves and Solutions to Common Challenges

-

Maximizing Investment: The Benefits of After-Sales Service for Best Ball Valve Control Valve Maintenance