The Best Enameled Aluminum Magnet Wire for Your Projects?

In the world of electrical engineering, selecting the right materials can make a significant difference. Enameled Aluminum Magnet Wire is one such material that deserves attention. The renowned expert, Dr. Emily Carter, once stated, "Choosing the right enameled aluminum magnet wire can enhance efficiency in countless applications."

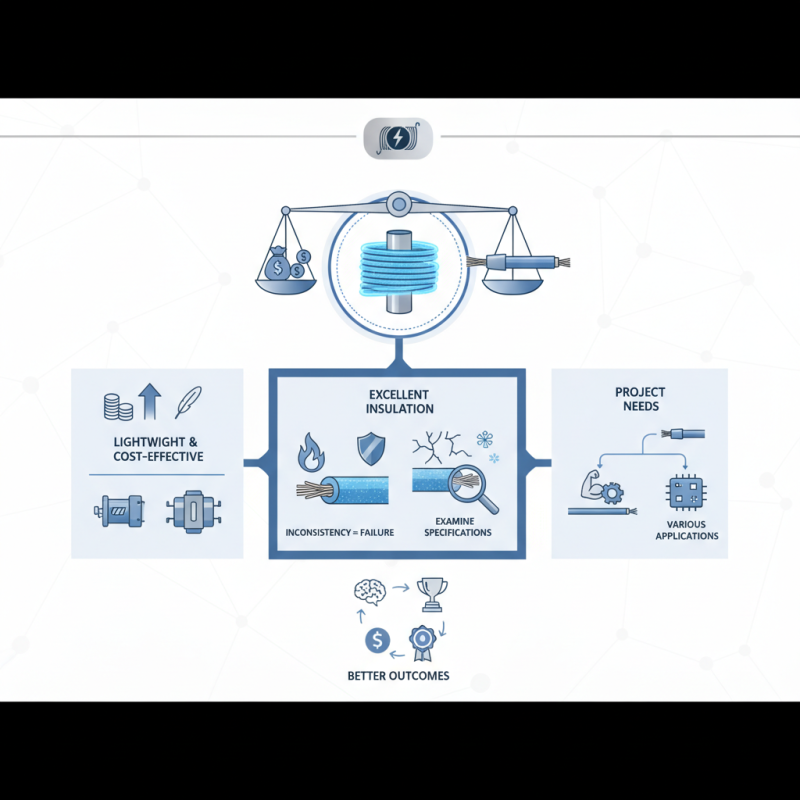

This wire is lightweight and cost-effective, ideal for various projects. Its unique enamel coating provides excellent insulation. However, not all enameled aluminum magnet wires are created equal. Some may not hold up under extreme conditions. This inconsistency can lead to unexpected failures in projects. It’s essential to examine specifications closely before committing to a product.

Furthermore, thinking critically about your specific project needs is crucial. Certain applications require high durability, while others may not. Balancing those requirements can be challenging. Many makers find themselves torn between cost and quality. A thoughtful approach can lead to better project outcomes and fewer surprises along the way.

What is Enameled Aluminum Magnet Wire?

Enameled aluminum magnet wire is a specialized type of wire. It features a thin layer of insulation made from enamel. This coating allows for better conductivity. Such wires are commonly used in electric motors, transformers, and other applications.

One notable aspect of enameled aluminum wire is its lightweight nature. It is often lighter than its copper counterpart. This can be advantageous in systems where weight is a concern. However, the trade-off is somewhat reduced conductivity. Aluminum has higher resistance than copper, which might lead to energy loss.

When selecting this wire, think about its uses. You need to consider the gauge size and insulation thickness. A thicker insulation layer offers better protection but can be bulkier. Reflecting on your project’s requirements is crucial. Not all applications will benefit equally from enameled aluminum wire. Sometimes, choosing the right kind of wire could significantly impact performance.

Properties and Benefits of Enameled Aluminum Wire

Enameled aluminum wire is an excellent choice for many projects. It offers unique properties that enhance performance. The wire is lighter than copper and has excellent conductivity. This makes it ideal for applications where weight is a concern. The enamel coating provides insulation, preventing short circuits.

When working with enameled aluminum wire, consider its flexibility. This wire can bend and twist without breaking. That feature is advantageous for winding coils in motors or transformers. However, the wire can be tricky to solder. The enamel must be stripped away before any connections.

Tips: Use a wire stripper designed for enameled wires. This will save time and frustration. Also, try to practice on scrap pieces first. Getting the technique right takes patience and practice. Take your time to avoid mistakes that could ruin your project.

The Best Enameled Aluminum Magnet Wire for Your Projects? - Properties and Benefits of Enameled Aluminum Wire

| Property | Description | Benefits |

|---|---|---|

| Conductivity | Aluminum has about 61% the conductivity of copper. | Lower cost compared to copper, making it a cost-effective choice for many applications. |

| Weight | Aluminum is significantly lighter than copper. | Easier to handle and reduces overall weight in applications. |

| Corrosion Resistance | Enameled coating provides a barrier against oxidation. | Increases longevity and performance in harsh environments. |

| Thermal Stability | Can withstand high temperatures without degrading. | Ideal for applications where heat resistance is crucial. |

| Flexibility | Highly flexible for various winding and shaping needs. | Easier to work with in complex designs and builds. |

Key Applications for Enameled Aluminum Magnet Wire

Enameled aluminum magnet wire is crucial in many industries. It is used in electric motors, transformers, and generators. These wires are lightweight and have excellent conductivity, making them a popular choice. According to a recent market report, the demand for enameled aluminum wire is expected to grow by 5% annually.

In electric motor applications, enameled aluminum wire performs well in high-performance environments. Its insulation properties help reduce energy loss. This wire can withstand high temperatures, which is critical in motor applications. However, not all wire types are well-suited for every environment. A review of several products showed varied performance levels.

Another key area is renewable energy systems. Enameled aluminum wire is frequently used in wind and solar energy applications. Its lightweight nature aids in energy efficiency. However, issues like oxidation can affect performance over time. Choosing the right coating can be a challenge. It's essential to evaluate these factors when selecting the ideal wire for a project.

The Best Enameled Aluminum Magnet Wire for Your Projects

How to Select the Right Enameled Aluminum Wire for Your Project

When selecting the right enameled aluminum wire for your projects, key factors include wire gauge, insulation thickness, and thermal rating. According to industry reports, wire gauge affects electrical resistance and overall performance. Thinner wires may overheat, impacting their lifespan. Aim for a wire gauge that aligns with your project requirements, striking a balance between flexibility and current capacity.

The insulation type also plays a significant role. A study from the Electrical Insulation Institute suggests that polyester and polyurethane coatings provide excellent abrasion resistance and thermal stability. These properties are essential for projects that endure harsh conditions. However, some may overlook the importance of proper soldering techniques, which can lead to compromised connections and reduced efficiency.

Additionally, consider the wire’s thermal rating, which impacts its operational limits. Most enameled aluminum wires can withstand up to 200°C, but exceeding this can lead to insulation breakdown. Choose wisely based on your project's thermal demands. Remember, while high-performance options exist, they may also come with increased costs. Reflect on your project's specific needs to make informed choices.

Maintenance Tips for Enameled Aluminum Magnet Wire

When working with enameled aluminum magnet wire, maintaining its integrity is crucial for optimal performance. According to recent industry studies, proper care can extend the life of your wire by up to 30%. Understanding how to store and handle this wire will prevent damage and ensure reliable functionality.

One key tip is to store the wire in a cool, dry place. Humidity can compromise the enamel insulation. Moisture may lead to corrosion, ultimately affecting conductivity. Additionally, avoid kinks or sharp bends in the wire during storage and installation. This could create weak points, which can easily fail under stress.

Cleaning the wire is also essential. Use a soft cloth to wipe off any dust. However, be cautious about abrasive materials that could scratch the enamel. Even subtle wear can expose the underlying aluminum, making it vulnerable to oxidation. Remember, a little care goes a long way. Always inspect your wire before use to catch any potential issues early.