Best Roll Lamination Machine for Your Business Needs?

Choosing the right Roll Lamination Machine is crucial for your business. Many companies rely on lamination for durability and presentation. With various models available, finding the best fit requires careful consideration.

When evaluating machines, think about the volume of work you handle. A high-speed Roll Lamination Machine may benefit larger operations. However, smaller businesses may prefer compact models that offer flexibility without sacrificing quality. It's essential to balance performance with your specific needs.

Do not overlook the importance of features. Some machines offer advanced settings, while others are more basic. This can impact your workflow and the quality of your finished products. Reflect on what features truly matter to you. Investing in the right machine can lead to better results. But, understanding your requirements is the first step.

Understanding Roll Lamination: Definition and Benefits

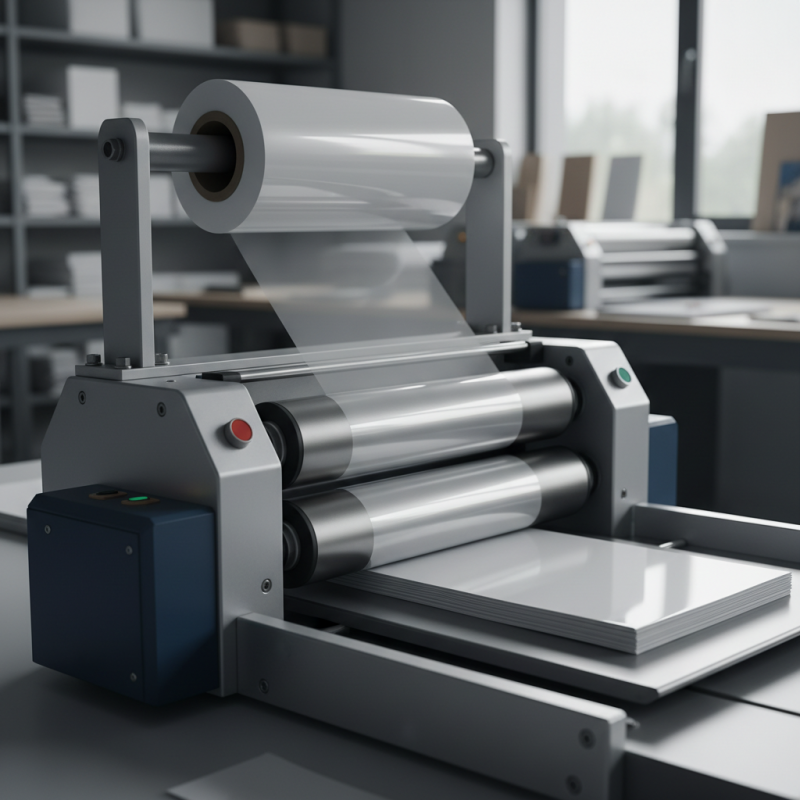

Roll lamination is a popular method for protecting and enhancing printed materials. It involves applying a plastic film over the surface of documents. This process creates a durable, moisture-resistant layer. Research indicates that nearly 60% of businesses prioritize lamination to improve document longevity.

The benefits of roll lamination are significant. It not only protects against wear and tear but also enhances the visual appeal of documents. A well-laminated piece can be up to three times more durable than non-laminated materials. However, it’s important to consider the type of materials being laminated. Some substrates may react poorly under heat.

Cost efficiency is another factor. While initial investments may seem high, studies suggest that lamination can save businesses up to 30% in printing costs over time. It's essential to weigh these savings against potential failures with improper lamination techniques. Inadequate equipment or experience can lead to inconsistencies, and that may require retraining staff. Being cautious with equipment choices is prudent; not all machines can deliver the same results.

Best Roll Lamination Machine for Your Business Needs

| Features | Description | Benefits | Suitable For |

|---|---|---|---|

| Speed | Up to 30 feet/minute | Increased productivity and efficiency | High-volume print shops |

| Film Width | Up to 25 inches | Versatile for various materials | Small to medium businesses |

| Temperature Control | Digital thermostat | Consistent lamination quality | Professional print services |

| Roll Diameter | 3 inches to 6 inches | Fewer roll changes required | Commercial printing |

| Weight | Approximately 100 lbs | Stable operation | Industrial applications |

Key Features to Consider When Choosing a Roll Lamination Machine

Choosing a roll lamination machine can feel overwhelming. There are several key features to consider for your business needs. Pay attention to the width of the machine. A wider machine can handle larger materials, which may improve efficiency. Look for adjustable temperature controls as well. This allows you to laminate various materials effectively.

Consider the speed of the machine. Some machines operate slowly, causing delays in production. A faster machine may be a bit pricier but could save time in the long run. Ease of use is another factor. Machines with complex controls can be frustrating. Simplicity often leads to better productivity. Also, take a close look at the build quality. A sturdy machine may be more durable and require less maintenance.

Finally, think about the size and weight of the machine. If space is limited, a compact model might be the best choice. Reflect on your specific needs. Not every feature will be necessary for your business. Be cautious of features that sound helpful but might not provide real value. It is essential to balance features and budget wisely. Finding the right machine is an investment in your operations.

Types of Roll Lamination Machines: A Comparative Overview

When considering roll lamination machines, various types cater to different business requirements. The primary classifications include thermal, cold, and pressure-sensitive laminators. Each type offers unique benefits depending on the materials being processed.

For instance, thermal laminators heat a film and adhere it to the substrate, resulting in a smooth finish. Industry reports indicate that over 70% of businesses prefer thermal options for their efficiency and high-quality output.

Cold laminators utilize adhesive rather than heat. They are ideal for heat-sensitive materials. This type accounts for roughly 20% of the market. Companies dealing with photographs or prints are often inclined toward cold laminators. Reports suggest this is a growing segment, as more users become aware of their advantages.

Pressure-sensitive laminators are another option, popular for their simplicity and ease of use. Operators sometimes face challenges with each type. For example, the potential for poor adhesion in cold laminators can lead to costly reprints.

Additionally, thermal machines may require regular maintenance, which can disrupt production. Identifying the right machine needs careful analysis of materials and workflows. It's essential to weigh these factors against expected output to make an informed choice.

Top Brands and Models for Roll Lamination in Different Industries

When selecting a roll lamination machine, it's crucial to consider the specific needs of your industry. Many organizations in sectors like education and print production rely on high-quality lamination for durability and presentation. According to a recent report by Smithers Pira, the global market for lamination machines is expected to reach $7.5 billion by 2026. This underscores the importance of effective machinery in maintaining product quality.

Different industries require unique features in lamination machines. For instance, educational institutions often prioritize ease of use and versatility. In contrast, those in the print industry may focus on speed and output quality. A study from MarketsandMarkets indicates that 60% of businesses value energy efficiency in their equipment. Investing in machines that meet these criteria can lead to significant cost savings over time.

However, businesses must also recognize potential drawbacks. Initial costs for high-quality laminators can be steep. Not all machines can handle varying film thicknesses well, leading to unsatisfactory finishes. A lack of after-sales support from suppliers can leave some companies in a tough spot. Reflecting on these aspects is essential for making informed purchasing decisions.

Maintenance Tips for Longevity of Your Roll Lamination Machine

Maintaining a roll lamination machine is crucial for optimal performance. Regular upkeep can prevent costly downtimes and extend the lifespan of your equipment. According to industry reports, machines with consistent maintenance can last up to 30% longer than those without it. Proper care can lead to improved efficiency, with reduced energy consumption by approximately 15%.

One important tip is to clean the rollers regularly. Dust and debris can accumulate, affecting the lamination quality. Use a soft cloth to wipe the rollers after each session. Additionally, lubricate the moving parts as recommended by the manufacturer. This can minimize friction and wear over time.

Monitoring temperature settings is also essential. Machines exposed to extreme heat can degrade faster. Ideally, keep the operating temperature within specified limits. Regularly check for any unusual noises or vibrations. Addressing these issues promptly can prevent major breakdowns. Always have a maintenance log to track repairs and adjustments. Noticing patterns could hint at potential problems before they escalate.

Best Roll Lamination Machine for Your Business Needs

The bar chart above illustrates key performance metrics of a roll lamination machine, including cost, speed, maximum width, weight, and warranty period. This information will assist you in selecting the most suitable machine for your business needs.