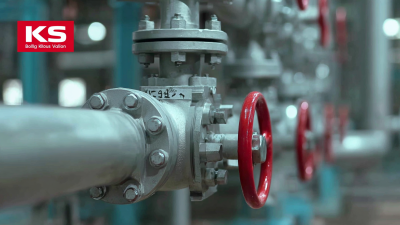

Challenges Faced by Global Buyers When Sourcing Flanged Ball Valves

In today's rapidly evolving industrial landscape, global buyers face numerous challenges when sourcing flanged ball valves, crucial components in various applications ranging from oil and gas to water treatment. According to a report by Market Research Future, the global ball valve market is expected to grow at a CAGR of 5.8%, reaching a valuation of approximately $9.3 billion by 2025. This growth underscores the increasing demand for flanged ball valves, yet challenges such as supply chain disruptions, varying quality standards, and fluctuating raw material prices persist. As buyers navigate these complexities, understanding alternative sourcing strategies becomes essential to ensure reliability and performance in their operations. This blog explores the hurdles faced by global buyers in sourcing flanged ball valves and examines potential alternatives that can mitigate these challenges.

Understanding Sourcing Challenges in the Flanged Ball Valve Market

Sourcing flanged ball valves in today’s global market presents a unique set of challenges for buyers. With the flanged ball valve market projected to reach $6.5 billion by 2025, as reported by Industry Research Market Insights, understanding the complexities involved in sourcing is essential. Buyers often encounter issues such as fluctuating raw material prices, which can dramatically impact procurement costs. For instance, the cost of stainless steel, a primary material used in flanged ball valves, increased by 25% over the past year, largely due to supply chain disruptions and increased demand from various industries.

Furthermore, navigating the diverse compliance and certification standards across different regions can complicate the sourcing process. Buyers must ensure that the valves they procure meet stringent regulations, such as API 608 and ISO 17292, which vary significantly from one country to another. According to a report by Global Market Insights, 60% of global buyers rank regulatory compliance as their top sourcing challenge. Consequently, a lack of uniform standards can lead to complications during shipping and delays in project timelines, ultimately affecting operational efficiency. Addressing these challenges requires a strategic approach to sourcing and vendor management, ensuring that quality and compliance do not take a backseat to cost considerations.

Navigating Quality Assurance Issues in Flanged Ball Valves

When sourcing flanged ball valves, global buyers often encounter significant quality assurance issues that can impact their procurement processes. One of the primary challenges is ensuring that the valves meet international quality standards. Given the variations in manufacturing practices across different countries, buyers must diligently verify the certifications and compliance of their suppliers. This involves not only assessing the documents provided but also conducting factory audits and product inspections to ensure that the final products adhere to specified performance criteria.

Another critical aspect of quality assurance is the material selection and the robustness of the manufacturing processes. Buyers must be aware that subpar materials can lead to premature failure, costly leaks, and operational inefficiencies. Therefore, it is essential to work closely with reliable suppliers who provide transparency about their sourcing and production methods. Furthermore, establishing strong communication channels for feedback and issue resolution can foster a more dependable supply chain, ultimately ensuring that the flanged ball valves sourced are of high quality and reliable performance.

Addressing Supply Chain Disruptions for Global Valve Buyers

In the competitive landscape of industrial procurement, global buyers of flanged ball valves are increasingly confronted with significant supply chain disruptions. Factors such as geopolitical tensions, natural disasters, and the lingering effects of the pandemic have severely affected the reliability of suppliers and the availability of critical components. These disruptions not only lead to delays in production timelines but can also drive up prices, making it imperative for buyers to adopt more strategic sourcing approaches.

To navigate these challenges, buyers must prioritize building robust relationships with multiple suppliers across different regions. Diversifying the supplier base can mitigate risks associated with over-reliance on a single source, providing greater flexibility during tumultuous times. Additionally, investing in supply chain technologies like real-time tracking systems and predictive analytics can enhance visibility and allow buyers to make informed decisions quickly. By embracing resilience and innovation in their sourcing strategies, global valve buyers can effectively address supply chain uncertainties and maintain the continuity of their operations.

Challenges Faced by Global Buyers When Sourcing Flanged Ball Valves

This bar chart represents the various challenges faced by global buyers when sourcing flanged ball valves, including supply chain disruptions, quality control issues, pricing fluctuations, and lead time delays.

Evaluating Compliance with International Standards in Valve Sourcing

When sourcing flanged ball valves, global buyers often encounter complexities related to compliance with international standards. These standards not only ensure the functionality and safety of the valves but also help in maintaining consistency across various industries. Navigating through the different certification processes can be daunting, especially for buyers unfamiliar with the specific regulations applicable in their regions.

Tip 1: Regularly update your knowledge on international standards such as API, ASME, and ISO to ensure your sourcing practices align with current requirements. This proactive approach can prevent potential setbacks during the procurement process.

Moreover, understanding local regulatory landscapes is crucial. Variations in standards from one country to another can lead to complications, including increased costs and delayed timelines. Buyers need to be vigilant in assessing the compliance status of manufacturers before finalizing orders.

Tip 2: Conduct thorough audits of potential suppliers to confirm their adherence to international standards. Request documentation, certifications, and even on-site visits if possible to assess the quality management systems in place.

By prioritizing compliance and diligence, global buyers can mitigate risks and secure high-quality flanged ball valves that meet their operational needs.

Challenges Faced by Global Buyers When Sourcing Flanged Ball Valves

| Challenge | Description | Impact on Sourcing | Compliance Standard |

|---|---|---|---|

| Quality Assurance | Ensuring products meet specified quality requirements and standards. | Delays in procurement, increased costs due to quality checks. | ISO 9001, API 607 |

| Regulatory Compliance | Adhering to different countries' regulations for safety and performance. | Legal penalties, product recalls, damage to reputation. | ASME, CE Marking |

| Supply Chain Disruptions | Unexpected interruptions affecting timely availability of products. | Increased lead times, potential loss of sales. | ISO 28000 |

| Technical Specifications | Difficulty in understanding and matching the technical requirements of different suppliers. | Miscommunication, incorrect orders leading to project delays. | API 6D, ASTM Standards |

| Currency Fluctuations | Changes in currency values impacting the cost of purchases. | Budget overruns, increased procurement costs. | None |

Mitigating Communication Barriers with Overseas Suppliers

Sourcing flanged ball valves often presents global buyers with significant challenges, particularly when it comes to effective communication with overseas suppliers. A report from Research and Markets indicates that 70% of procurement managers cite communication barriers as one of the leading hurdles in international sourcing. The nuances of language differences, cultural misunderstandings, and varying regulatory standards can easily complicate negotiations and product specifications. Without clear communication, the risk of receiving incorrect or substandard products increases, potentially leading to costly delays and project setbacks.

Sourcing flanged ball valves often presents global buyers with significant challenges, particularly when it comes to effective communication with overseas suppliers. A report from Research and Markets indicates that 70% of procurement managers cite communication barriers as one of the leading hurdles in international sourcing. The nuances of language differences, cultural misunderstandings, and varying regulatory standards can easily complicate negotiations and product specifications. Without clear communication, the risk of receiving incorrect or substandard products increases, potentially leading to costly delays and project setbacks.

To mitigate these issues, companies are adopting various strategies to enhance their communication processes. Leveraging technology, such as collaborative platforms and translation tools, has proven effective in bridging the gap between buyers and suppliers. A study from IDC highlights that organizations utilizing digital tools for communication can reduce misunderstandings by up to 50%. Additionally, establishing a local liaison or employing bilingual staff can facilitate smoother interactions, ensuring that both parties are aligned on expectations and requirements. By proactively addressing communication barriers, global buyers can improve their sourcing efficiency and build stronger, more reliable relationships with their international partners.

Related Posts

-

Maximizing Investment: The Benefits of After-Sales Service for Best Ball Valve Control Valve Maintenance

-

Real World Applications of Best Ball Valves and Solutions to Common Challenges

-

Leading Global Manufacturers of Best Flow Control Valve for International Buyers

-

7 Essential Tips for Selecting Top Manufacturers of Best Automation Valves in 2024

-

Ultimate Guide to Comparing the Best Automatic Valves for Your Procurement Needs

-

Solutions for Optimizing Fluid Dynamics with the Best Flow Valve in Global Industries