How to Choose the Right Damper Actuator for Your System?

Choosing the right Damper Actuator is crucial for optimal system performance. This decision can greatly influence efficiency and functionality. Various factors come into play when making this choice, so careful consideration is essential.

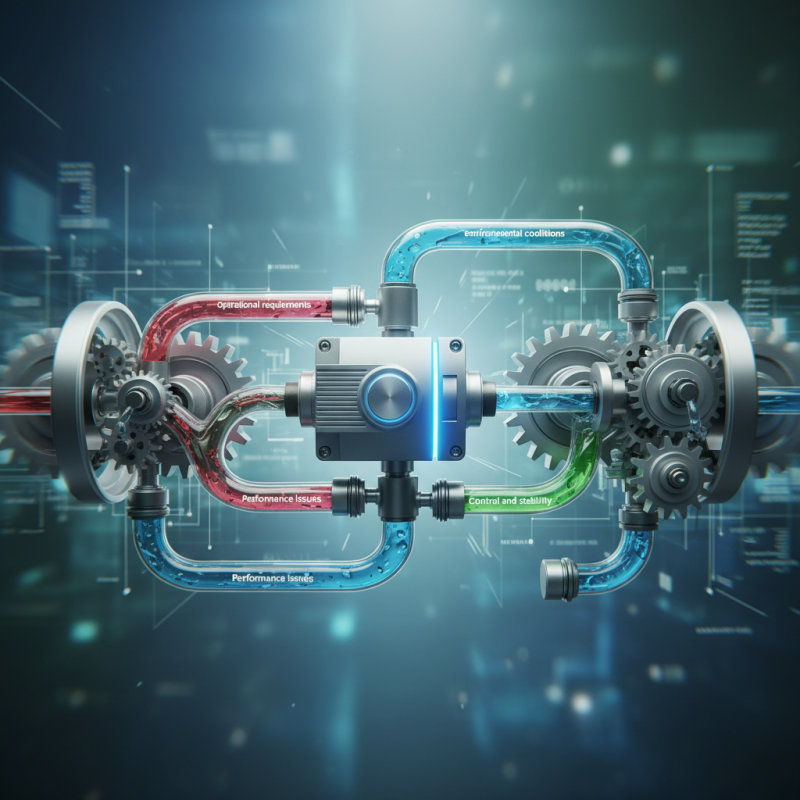

Look at the system's specifications. Understand your operational requirements and environmental conditions. A well-chosen damper actuator can enhance control and stability. However, some may overlook the importance of compatibility with existing components. This mistake can lead to performance issues.

Consider the types available on the market. Each has unique features and benefits. A mismatch could cause frustration and inefficiency. Reflect on your specific needs. Choosing wisely can significantly impact overall efficiency and effectiveness. Failure to do so may result in costly adjustments down the line.

Understanding Different Types of Damper Actuators Available in the Market

When selecting a damp actuator, it’s crucial to understand the various types available. Combustion air control valves often use electric actuators. These offer precise positioning and quick response times, making them ideal for HVAC systems. On the other hand, pneumatic actuators are commonly found in larger installations. They provide strong torque and can handle high loads but may require more complex setups.

According to industry reports, approximately 40% of HVAC issues stem from improper actuator selection. Actuators can be linear or rotary. Linear types move along a straight path, suitable for straight dampers. Rotary actuators operate on a pivot and are better for circular dampers. It's essential to consider the size and application before selecting. Many engineers overlook these details, which can lead to inefficiencies and increased operational costs.

Another factor is control compatibility. Some systems use proportional controls, while others rely on on/off controls. Misalignment in control types can lead to functionality problems. A study concluded that 30% of maintenance issues could be traced back to actuator control mismatches. Contractors must pay attention to these aspects to avoid costly mistakes down the road. This underlines the importance of a thorough selection process and careful system evaluation.

Key Specifications to Consider When Selecting a Damper Actuator

When selecting a damper actuator, consider key specifications that ensure optimal performance. Start by evaluating the torque requirements. The torque determines how well the actuator can operate under different conditions. Ensure that the selected actuator meets the torque needs of the specific damper in your system.

Power supply specifications are also crucial. Some actuators require AC, while others function on DC power. Incorrect power supply can lead to malfunctions. It’s important to check the voltage ratings and ensure compatibility.

Tips: Always verify the actuator’s speed settings. A faster actuator can adjust dampers quickly, but it may produce more wear over time. Assess the operational environment as well. Conditions like temperature and humidity can impact actuator performance.

Another significant aspect is the communication protocol. Select an actuator that suits your system's control method, whether it's analog, digital, or a combination. Remember, compatibility is key to smooth operation.

Take time to reflect on your system requirements. Each application may have unique demands. A well-considered choice now can prevent future headaches. Evaluate your options carefully.

Evaluating Actuator Performance: Torque, Speed, and Control Options

When evaluating damper actuators, three key performance aspects come into play: torque, speed, and control options. Torque defines the strength of the actuator. It dictates how efficiently it can open or close a damper. Opting for an actuator with adequate torque ensures your system operates smoothly. Check the damper's specifications before making a decision.

Speed is equally important. It affects how quickly your system responds to changes. An actuator that operates too slowly may lead to delayed responses in critical situations. Your system's requirements dictate the optimal speed. Consider potential fluctuations in your application environment for accurate assessment.

**Tips**: Always balance torque and speed. High torque with low speed may work for large dampers, but it won't suit smaller ones. Moreover, consider your control options. Some actuators offer more precise control and can integrate with existing systems. A mismatch in control capabilities can hinder performance.

Evaluate all factors thoroughly. Some actuators may look appealing at first glance but fail under real-world conditions. Relying solely on technical specifications can lead to oversight. Make time for hands-on testing where possible to better understand the actuator's performance. This reflection often reveals hidden issues.

How to Choose the Right Damper Actuator for Your System? - Evaluating Actuator Performance: Torque, Speed, and Control Options

| Actuator Type | Torque (Nm) | Speed (sec/90°) | Control Options | Power Supply (V) |

|---|---|---|---|---|

| Linear Electric Actuator | 100 | 5 | 0-10V, 4-20mA | 24 |

| Rotary Pneumatic Actuator | 150 | 3 | On/Off, Proportional | Air Supply |

| Electric Rotary Actuator | 75 | 4 | Modulating Control | 230 |

| Hydraulic Actuator | 200 | 6 | On/Off | Hydraulic Pressure |

| Servo Actuator | 50 | 2 | Digital Control, PID | 12 |

Analyzing Application-Specific Requirements for Damper Actuation

When selecting a damper actuator, consider the specific needs of your application. The environment plays a crucial role. Is it indoors or outdoors? High humidity or high temperatures can impact actuator performance. It's essential to align the actuator's specifications with these conditions.

Next, think about the control requirements. Do you need precise position control or simple open/close functionality? An actuator designed for high precision may come at a higher cost. Assess whether this investment is necessary based on your system's performance needs. Sometimes, basic functions may suffice for simpler applications, traditionally prompting further reflection on your technical demands.

Installation considerations are also critical. Space can be a constraint in many setups. An actuator that fits well within the existing architecture saves time and effort. Additionally, think about the maintenance aspects. Some actuators may require frequent checks. Others might be more reliable. Weigh these factors against your operational goals. Not all aspects might seem perfect, but thoughtful reflection can lead to a better choice.

Industry Standards and Compliance Factors in Damper Actuator Selection

When selecting a damper actuator, industry standards play a critical role. Different sectors, such as HVAC and industrial automation, dictate specific compliance requirements. For example, the American National Standards Institute (ANSI) sets guidelines for actuator performance. Meeting these standards ensures safety and efficiency. Recent reports show that systems adhering to ANSI standards experience 25% fewer failures over five years.

Understanding compliance factors is essential. The International Organization for Standardization (ISO) offers frameworks that improve actuator reliability. Compliance with ISO 9001 can enhance quality management during the selection process. Interestingly, studies indicate that maintaining alignment with these norms can reduce operational costs by about 15%. This reduction stems from fewer maintenance interventions and increased system lifespan.

Choosing actuators without considering compliance can lead to issues. Some installations face penalties for not meeting jurisdictional requirements. It’s crucial to assess these factors during the selection process. Users often overlook the long-term implications of non-compliance. Proper research can save time and resources. Ultimately, the choice of a damper actuator should reflect both performance and adherence to established standards.