How to Choose the Right High Temperature Ball Valve for Your Industry Needs

In a wide range of industrial applications, selecting the appropriate High Temperature Ball Valve is crucial for ensuring safety, efficiency, and performance. With the increasing demand for systems that can withstand extreme temperatures, it becomes imperative to understand the various types and specifications of these valves to meet specific industry needs. Whether you're involved in chemical processing, oil and gas, or power generation, the right High Temperature Ball Valve can significantly impact your operations.

This blog aims to guide you through the essential factors to consider, helping you make informed decisions when choosing the optimal valve for your industrial applications. We'll explore various options, performance metrics, and the latest advancements in valve technology, ensuring that you have all the insights necessary to select the ideal solution tailored to your requirements.

Key Considerations for Selecting High Temperature Ball Valves in Industrial Applications

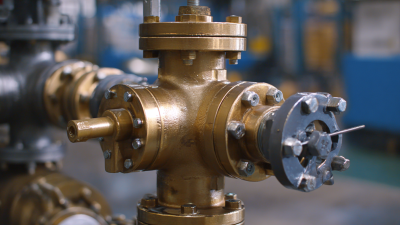

When selecting high temperature ball valves for industrial applications, there are several key considerations that can significantly impact performance and longevity. One crucial factor is the valve material; stainless steel is often recommended due to its excellent corrosion resistance and ability to withstand high temperatures. According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), materials like forged steel and special alloys, such as Inconel, are increasingly used in high-stress environments, enhancing durability and reliability under extreme conditions.

Another important aspect to consider is the valve's pressure rating and size. The American Society of Mechanical Engineers (ASME) specifies that high temperature ball valves should comply with specific pressure standards, such as ASME B16.34, ensuring they can handle the operating pressures typical in industries like oil and gas. Size selection also plays a critical role; valves that are too large may cause issues like fluid turbulence, while overly restrictive valves can lead to pressure drop and increased wear. A study by the Valve Manufacturers Association of America indicated that incorrectly sized valves can reduce system efficiency by up to 30%, underscoring the need for precise calculations during the selection process.

Comparison of Alternative Valve Types: Benefits and Drawbacks in High-Temperature Settings

In high-temperature applications, selecting the appropriate valve type is crucial for maintaining system integrity and efficiency. Among the common alternatives to high-temperature ball valves are gate valves and globe valves.

Gate valves are designed to provide minimal flow resistance when fully open, ideal for on/off service in high-pressure conditions. However, they may struggle with throttling and are less effective in systems requiring precise flow regulation. Globe valves, on the other hand, can offer better flow control due to their design, but their pressure drop can be significant, making them less ideal for high-temperature and high-flow applications.

When deciding on the best valve type for your needs, consider the specific operating conditions. A high temperature ball valve is often preferred for its robust sealing capabilities and long service life. However, if your application requires frequent adjustments, a globe valve might be more suitable despite its drawbacks.

Tip: Always evaluate the media type and its properties to gauge compatibility with valve materials.

Tip: Conduct a thorough thermal analysis to understand how temperature affects each valve type's performance to ensure optimum selection.

Impact of Material Selection on High Temperature Ball Valve Performance and Longevity

When selecting a high temperature ball valve, the impact of material selection is crucial for ensuring optimal performance and longevity. High temperature applications, often exceeding 200°C, necessitate materials that can withstand both thermal stress and corrosive environments. According to a 2021 industry report by the Valve Manufacturers Association, nearly 35% of valve failures in high temperature settings are attributed to inadequate material properties. For instance, stainless steel alloys like ASTM A182 F316 are commonly favored for their strength and resistance to oxidation, making them suitable for steam and gas applications.

Moreover, the longevity of high temperature ball valves heavily relies on the choice of seat and seal materials. Advanced materials like PTFE composites are known for their durability in extreme conditions, maintaining sealing integrity over extended periods. A study published in the Journal of Materials Science highlighted that valves using PTFE seals showed a 20% improvement in service life compared to those using standard rubber elastomers under high temperature conditions. Thus, choosing the right materials not only enhances performance but also reduces downtime and maintenance costs, making it an essential consideration for industries such as petrochemicals and power generation.

Industry-Specific Standards and Certifications for High Temperature Ball Valves

When selecting high temperature ball valves for specific industry applications, it's crucial to consider the relevant standards and certifications. For instance, the American Society of Mechanical Engineers (ASME) sets forth the ASME B16.34 standard, which outlines the requirements for the design, materials, and testing of valves used in high-pressure and high-temperature applications. Compliance with this standard ensures that the valves can withstand the operational demands of industries such as oil and gas, chemical processing, and power generation.

Additionally, the American Petroleum Institute (API) has established standards like API 608, which specifies the requirements for the design and performance of ball valves used in the petroleum and natural gas industries. Valves that meet API standards are rigorously tested for leakage rates and durability under extreme conditions, ensuring that they can perform reliably in applications involving high-temperature fluids. According to a market analysis report by Research and Markets, the global market for high temperature ball valves is expected to grow significantly, driven by the rising demand for efficient and durable components in industrial processes. As such, selecting valves that adhere to these industry-specific standards is essential for ensuring safety, compliance, and operational efficiency.

How to Choose the Right High Temperature Ball Valve for Your Industry Needs

| Industry | Temp Range (°C) | Material | Standards & Certifications | Recommended Valve Type |

|---|---|---|---|---|

| Oil & Gas | -20 to 250 | Carbon Steel | API 6D, ISO 9001 | Full Port Ball Valve |

| Chemical Processing | -10 to 200 | Stainless Steel | ASME B16.34, UL 594 | Trunnion Mounted Ball Valve |

| Power Generation | 0 to 300 | Alloy Steel | ANSI B31.1, NACE MR0175 | Segmented Ball Valve |

| Pharmaceuticals | 10 to 150 | 316L Stainless Steel | FDA, EHEDG | Sanitary Ball Valve |

| HVAC | -5 to 120 | Copper | ASHRAE, AHRI | Ball Valve with Actuator |

Cost-Benefit Analysis of High Temperature Ball Valves Versus Alternative Options in the Market

Choosing the right high temperature ball valve involves not just technical specifications but also a thorough cost-benefit analysis compared to alternative options. Recent industry reports indicate that high temperature ball valves can improve process reliability by up to 20% and can withstand temperatures up to 500°F, making them ideal for industries such as oil and gas, chemical manufacturing, and power generation. However, while the initial investment may be higher—often 15-30% more than gate or globe valves—the durability and reduced maintenance frequency of ball valves can lead to lower long-term operational costs.

When evaluating these valves, companies should consider the total cost of ownership, which includes installation, maintenance, and downtime costs. For instance, a well-maintained high temperature ball valve can last over 15 years, while other valve types may require replacement every 5-7 years. This longevity can save industries significant costs, particularly in applications involving high-pressure systems where faulty valves can lead to costly shutdowns.

Tip: Conduct a life cycle cost analysis to understand the benefits over time. Another useful practice is to consult with suppliers about warranty and support options that can mitigate initial investment risks. Prioritize valves that are certified for both performance and safety, ensuring compliance with industry standards and regulations.

Related Posts

-

Finding Quality Suppliers for Best High Temperature Ball Valves: The Ultimate Guide to Ensuring Durability and Performance

-

Maximizing Investment: The Benefits of After-Sales Service for Best Ball Valve Control Valve Maintenance

-

Solutions for Optimizing Fluid Dynamics with the Best Flow Valve in Global Industries

-

Exploring the Characteristics and Applications of Best Valve Valves: A Comprehensive Guide for Global Buyers

-

Addressing Common Issues with High Pressure Valve Performance

-

2025 Tech Trends in Automation Valves: How to Choose the Best Solutions for Your Industry