How to Choose the Right Sandblast Rubber Hose for Your Needs?

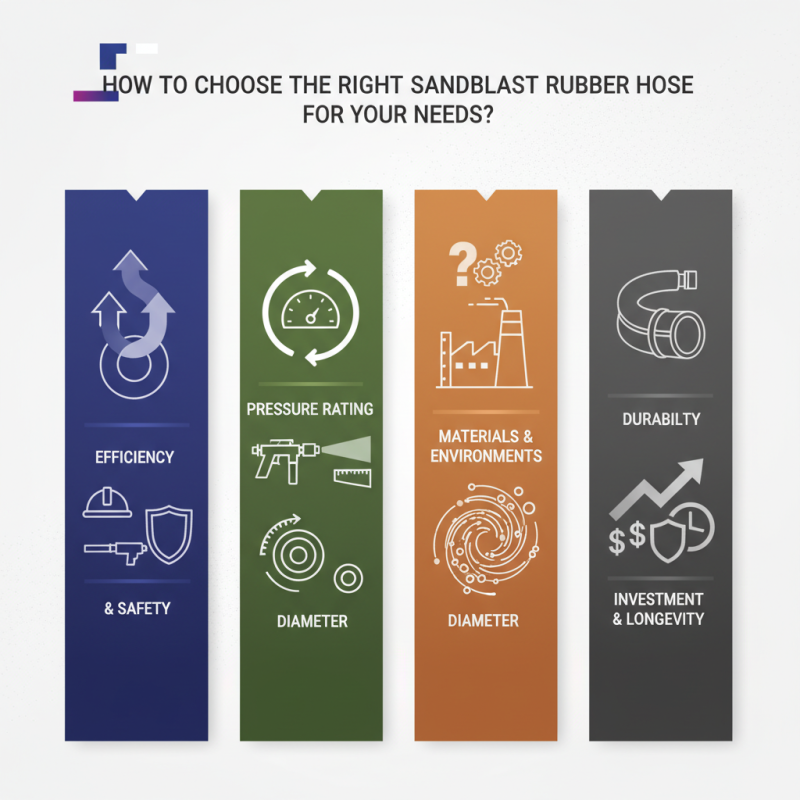

Choosing the right Sandblast rubber hose is crucial for effective sandblasting operations. A proper hose can increase efficiency and safety. However, many people overlook this essential piece of equipment.

When selecting a sandblast rubber hose, consider the pressure rating and diameter. Different projects require different specifications. A hose that is too small can restrict airflow and reduce performance. On the other hand, a hose that is too large may be cumbersome and difficult to use.

Some hoses are designed for specific materials or environments. It’s important to reflect on your specific needs. Many forget to think about the durability of the hose. A low-quality hose can wear out quickly, causing delays. An investment in a resilient sandblast rubber hose often pays off. Remember, the right choice can enhance your sandblasting experience significantly.

Understanding Sandblast Rubber Hoses: Key Features to Consider

Understanding sandblast rubber hoses is crucial for ensuring optimal performance. These hoses are designed to withstand high pressure and abrasion. They play a vital role in blasting operations, where the right hose can significantly affect efficiency.

When choosing a sandblast rubber hose, consider the inner diameter and length. A report from the Industrial Rubber Products Association indicates that hoses with larger diameters decrease pressure loss. This improves the sandblast jet. Additionally, the length must match your operational needs. Too long can create unnecessary friction; too short can hinder movement.

Another key feature to evaluate is the material construction. High-quality hoses are usually made from synthetic rubber or reinforced compounds. These materials boost durability and flexibility. The Hose Manufacturers Association highlights that flexibility is essential for maneuverability. However, low-quality alternatives might crack or weaken under pressure. Always assess the hose's pressure rating, as inadequate ratings can lead to failures during operations.

Sandblast Rubber Hose Features Comparison

This chart compares key features of sandblast rubber hoses based on performance ratings across important criteria such as abrasion resistance, pressure rating, temperature range, flexibility, and weight.

Identifying Your Specific Needs for Sandblasting Applications

Choosing the right sandblast rubber hose requires a clear understanding of your specific needs. Consider the type of material you will be blasting. Different materials demand different hose properties. For instance, harder materials may require thicker hoses to withstand the pressure. The hose length is also crucial. A longer hose can give you more reach but may decrease pressure.

Tips: Measure your workspace carefully. It’s better to have a slightly longer hose than one that’s too short.

Pressure rating is another vital factor. Ensure the hose can handle the pressure your equipment uses. Using a hose with a lower rating can lead to dangerous situations. Temperature fluctuations can also impact hose performance. Ensure your hose can withstand both hot and cold conditions.

Tips: Look for hoses that are tested under extreme conditions. Sometimes, a hose may look perfect but perform poorly in real applications.

Remember, not every hose is universal. Compatibility with your equipment matters. Check fittings and connectors. This can save you time and frustration down the line. Refining your needs can lead to more effective sandblasting.

Evaluating Material Durability and Flexibility in Rubber Hoses

When selecting a sandblast rubber hose, material durability and flexibility are key factors. Many hoses are made from various rubber compounds. According to industry reports, synthetic rubber offers greater durability than natural rubber. This helps the hose withstand abrasive materials. A durable hose can last significantly longer, reducing replacement costs and downtime.

Flexibility is equally important in sandblast applications. A highly flexible hose can bend around corners without kinking. Reports suggest that hoses with a bend radius of less than 5 inches perform better in tight spaces. However, flexibility often comes at a cost to durability. Users may find that a more flexible hose wears out faster. This creates a dilemma when choosing the right option. It's a balancing act between flexibility and durability.

Color and thickness also influence performance. A darker hose may indicate added strength and chemical resistance. Thicker hoses tend to handle higher pressures as well. However, thicker hoses might be less flexible. Users must evaluate their specific needs. Not every hose will be suitable for every task. Some trials are necessary to find the perfect fit for unique conditions.

Comparing Hose Sizes and Fittings for Optimal Performance

When selecting a sandblast rubber hose, hose size and fittings play a crucial role. A poorly sized hose may lead to inefficient performance. According to a 2022 industry report, proper hose diameter can improve air flow by up to 15%. This can significantly impact the effectiveness of the sandblasting process.

Fittings must also be compatible with the hose size. Mismatched fittings create leaks and reduce pressure. An industry survey indicated that 75% of users experienced issues due to improper fittings. Using larger fittings may seem tempting, but they can cause turbulence. Turbulence decreases efficiency, wasting both time and materials.

It's essential to consider the specific application when choosing sizes and fittings. Some projects may require higher pressure, while others need flexibility. Ignoring these aspects can result in subpar outcomes. Always double-check specifications. Remember, the smallest detail can make a difference.

Maintenance Tips for Prolonging the Life of Sandblast Hoses

Maintaining sandblast hoses is crucial for longevity. Regular checks can prevent costly replacements. According to industry reports, proper maintenance can extend hose life by 30%. Small issues can escalate quickly.

Inspect your hoses often. Look for wear, cracks, or abrasions. Replace any damaged parts immediately. Signs of deterioration may mean deeper problems. Keep the hoses clean, free from sand buildup. Even small particles can cause wear over time.

Storage is vital for prolonging hose life. Keep hoses coiled properly to avoid kinks. Exposing hoses to extremes can lead to damage. Store them in a cool, dry place. Remember, high temperatures can weaken rubber. Proper cleaning can also enhance performance. Use mild detergents, not harsh chemicals.

Check connections and fittings regularly. Loose connections can cause leaks, leading to inefficiency. Tighten or replace them as needed. Small leaks can waste resources and hinder productivity. Proper maintenance is more than keeping equipment operational. It's about ensuring long-term efficiency and safety.