7 Essential Benefits of Choosing Valve Ball Valves for Your Piping Systems

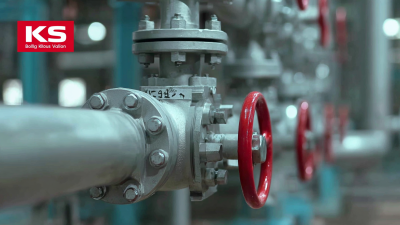

In the ever-evolving landscape of industrial piping systems, the selection of the right valve type plays a crucial role in ensuring efficiency, safety, and longevity. Among the various options available, the Valve Ball Valve stands out as a preferred choice for many engineers and operators. According to a report by Grand View Research, the global industrial valve market is projected to reach USD 85.74 billion by 2027, with ball valves representing a significant portion due to their superior performance and reliability. The ease of operation, quick shut-off capabilities, and durable construction of Valve Ball Valves make them ideal for an array of applications, from oil and gas to municipal water systems. This ultimate guide delves into seven essential benefits of choosing Valve Ball Valves for your piping systems, highlighting why they are an indispensable component in modern industrial applications.

Key Advantages of Valve Ball Valves Over Traditional Valve Types

When it comes to selecting valves for piping systems, valve ball valves stand out for their superior performance compared to traditional valve types, such as gate or globe valves. One key advantage is their exceptional flow control. The design of ball valves allows for minimal flow resistance, making them ideal for applications where fluid speed matters. Unlike traditional valves that may exhibit pressure drops, ball valves ensure a streamlined flow, which can lead to increased efficiency in system operations.

Another significant benefit is their durability and longevity. Ball valves are constructed with robust materials that can withstand high pressures and temperatures, making them suitable for a wide range of industrial environments. They are less prone to wear and tear compared to other valve types, which often require regular maintenance and eventual replacement. This durability translates into lower long-term costs and less downtime, allowing systems to operate smoothly and reliably. Furthermore, the easy operation of ball valves—often requiring just a quarter turn to open or close—enhances user convenience and safety, making them a preferred choice in modern piping systems.

Understanding the Mechanism: How Valve Ball Valves Work in Piping Systems

Ball valves are vital components in piping systems, recognized for their efficient operation and reliability. The mechanism behind a ball valve's functionality is relatively simple yet highly effective. At the core of the valve lies a spherical disc, or "ball," that features a central hole. This design allows for quick regulation of flow; when the ball is rotated a quarter turn, the hole aligns with the pipe, enabling fluid to flow freely. Conversely, when the ball is turned away, the flow is stopped, providing a clear and definitive shut-off.

The smooth surface of the ball creates minimal resistance to flow, which reduces pressure drop and turbulence within the piping system. Additionally, ball valves are equipped with a sealing mechanism that provides a tight closure, preventing leaks. This makes them particularly suitable for high-pressure and high-temperature applications. The ease of operation, combined with their durability and low maintenance needs, positions ball valves as a top choice for various industrial and residential piping systems. Their straightforward mechanism not only enhances operational efficiency but also extends the lifespan of the entire system.

Maintaining Efficiency: The Role of Valve Ball Valves in Fluid Control

Valve ball valves are instrumental in maintaining efficiency within piping systems, particularly in fluid control applications. Their design allows for a tight seal that minimizes leakage, ensuring that fluids flow smoothly without waste. This feature is especially crucial in industries where pressure and flow rates must be precisely managed. By using valve ball valves, operators can maintain optimal system performance while also reducing operational costs associated with potential leaks.

Moreover, the versatility of valve ball valves makes them suitable for various fluids, including corrosive substances and gases. Their ability to withstand high pressure and temperature further enhances their functionality in demanding environments. This adaptability means that they can be seamlessly integrated into existing piping systems, yielding significant improvements in efficiency and safety. Overall, the role of valve ball valves in fluid control is vital, offering reliable performance that enhances the overall effectiveness of piping systems.

Enhancing Durability: Why Valve Ball Valves Stand the Test of Time

When it comes to maintaining the longevity and efficiency of piping systems, valve ball valves are an essential choice. Their design features a spherical disc, allowing for smooth flow control and minimal turbulence, which significantly enhances system durability. Unlike other valve types, ball valves can withstand high pressures and temperatures, making them ideal for various applications, from residential plumbing to industrial processes. With advancements in materials and construction, today's ball valves can resist corrosion and wear, ensuring they remain reliable even in challenging environments.

Recent studies have highlighted the importance of quality in valve construction, particularly as concerns over lead leaching in brass devices come to light. This has elevated the need for robust valve solutions that not only adhere to safety standards but also provide longevity in performance. The integration of innovative materials and designs, such as those seen in new valve guides for internal combustion engines, showcases the engineering improvements that enhance durability. As industries increasingly turn towards sustainable and reliable solutions, valve ball valves stand as a testament to modern engineering, proving that investing in quality can lead to long-term benefits for both efficiency and safety in piping systems.

Cost-Effectiveness: Long-Term Savings with Valve Ball Valves in Your Infrastructure

Cost-effectiveness is a crucial factor in infrastructure management, especially when it comes to the selection of components like

valves. Valve ball valves stand out as a cost-effective solution for piping systems due to their

durability and efficiency. Constructed from high-quality materials, these valves not only resist

corrosion and wear but also minimize maintenance needs. This translates to fewer replacements and repairs over time, leading to significant long-term savings for businesses.

Cost-effectiveness is a crucial factor in infrastructure management, especially when it comes to the selection of components like

valves. Valve ball valves stand out as a cost-effective solution for piping systems due to their

durability and efficiency. Constructed from high-quality materials, these valves not only resist

corrosion and wear but also minimize maintenance needs. This translates to fewer replacements and repairs over time, leading to significant long-term savings for businesses.

Moreover, valve ball valves are designed for optimal flow control. Their design facilitates a smooth passage and reduces

pressure loss, thereby enhancing system performance. This efficiency means lower energy consumption and decreased operational costs, further contributing to

financial savings. By investing in valve ball valves, companies can achieve a reliable and cost-effective piping system that delivers consistent performance while protecting their

bottom line.

Related Posts

-

Exploring Future Trends in Best Way Ball Valve After Sales Service and Maintenance Cost Efficiency

-

Real World Applications of Best Ball Valves and Solutions to Common Challenges

-

Finding Quality Suppliers for Best High Temperature Ball Valves: The Ultimate Guide to Ensuring Durability and Performance

-

Maximizing Investment: The Benefits of After-Sales Service for Best Ball Valve Control Valve Maintenance

-

How to Choose the Right High Temperature Ball Valve for Your Industry Needs

-

Unveiling New Opportunities for Flow Valves at the Record Breaking Canton Fair 2025