10 Essential Flow Valves You Must Know for Efficient Global Procurement

In the world of global procurement, understanding the various types of Flow Valves is crucial for ensuring efficient operations and cost-effective supply chain management. As industries strive for optimized performance, the demand for high-quality valves has surged, leading procurement professionals to explore a range of alternatives that not only meet technical specifications but also contribute to sustainability and operational efficiency. This blog delves into the ten essential Flow Valves that are pivotal for anyone involved in global procurement, highlighting their unique features, advantages, and the innovative alternatives available in today's market. By shedding light on these critical components, we aim to empower procurement specialists to make informed decisions that drive success in their organizations.

Key Features to Consider When Selecting Flow Valves for Global Procurement

When selecting flow valves for global procurement, understanding the key features is crucial for ensuring efficiency and reliability. Flow valves play an essential role in various industries, including oil and gas, water treatment, and manufacturing. According to a report by MarketsandMarkets, the global valve market is expected to grow from $64.2 billion in 2021 to $82.6 billion by 2026, representing a compound annual growth rate (CAGR) of 5.1%. This growth highlights the increasing demand for high-quality flow valves, emphasizing the necessity of carefully considering their features during procurement.

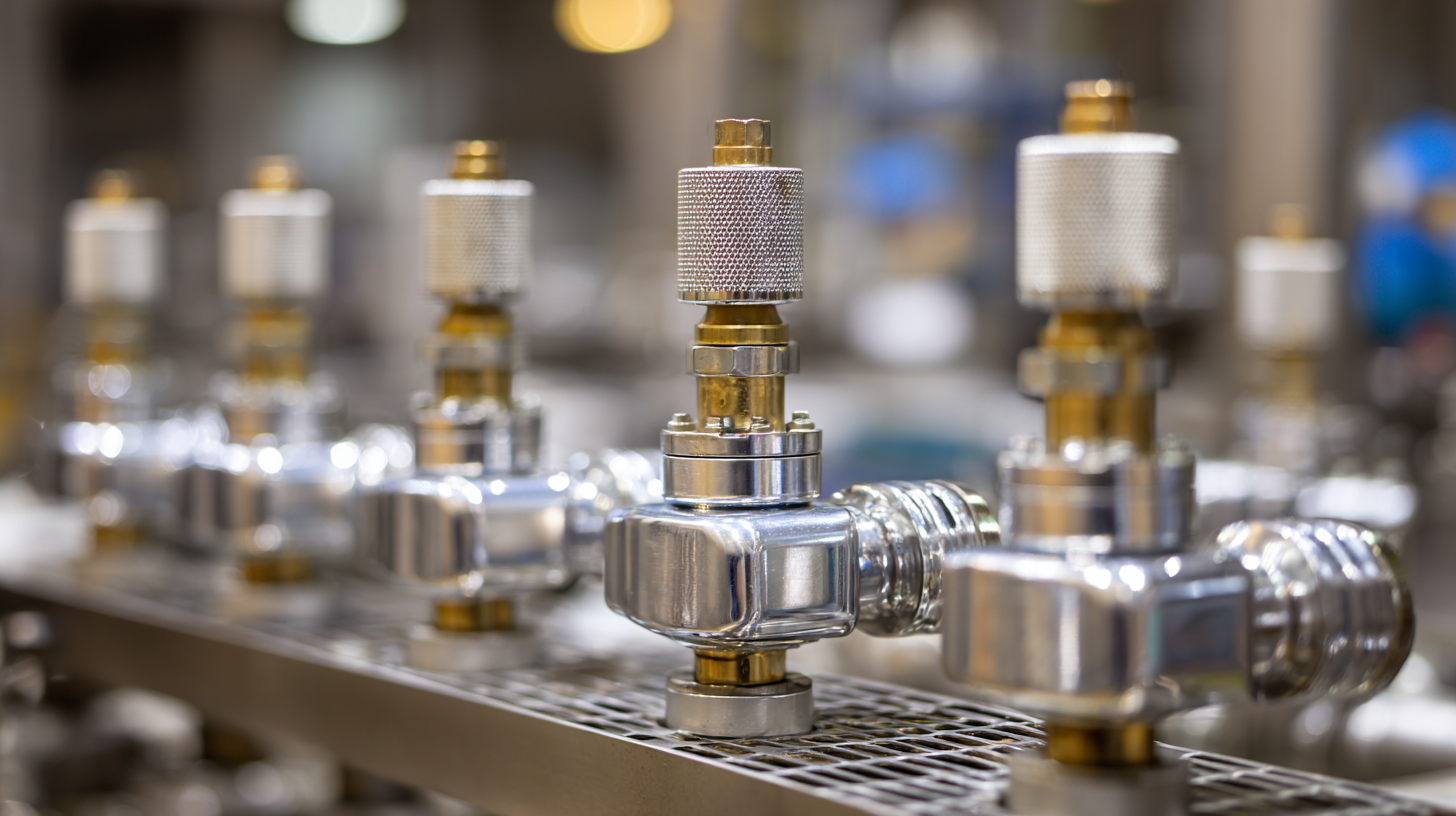

One of the primary features to consider is the valve material, which significantly impacts corrosion resistance and durability. For instance, stainless steel valves are often preferred for their longevity and ability to withstand harsh environments. Additionally, the valve type, such as ball, globe, or butterfly, should align with specific application requirements. The International Journal of Engineering Research & Technology has noted that the right valve type can enhance operational efficiency by up to 20%. Lastly, the size and pressure rating are integral to ensuring that the flow valves can handle the intended fluid flow without leakage or failure, making these selections vital to successful global procurement strategies.

Top 5 Types of Flow Valves Crucial for International Supply Chains

Flow valves play a critical role in international supply chains, ensuring that fluids are managed efficiently and effectively across various sectors. Among the top five types of flow valves essential for global procurement are ball valves, globe valves, gate valves, check valves, and butterfly valves. According to a recent report by Markets and Markets, the global flow control market is expected to reach $34 billion by 2026, growing at a CAGR of 5.8%. This increase underscores the importance of selecting the right valves to optimize operations and reduce costs in global supply chains.

Ball valves are particularly noteworthy for their durability and reliability, making them ideal for high-pressure applications. In contrast, globe valves offer superior throttling capabilities, which is crucial for controlling flow rates accurately in industrial processes. Additionally, check valves are essential for preventing backflow, which can safeguard supply chains from fluid contamination and improve overall system efficiency. As the demand for efficient fluid management continues to rise, understanding the diverse applications of these flow valves will be crucial for procurement professionals aiming to enhance operational performance and maintain competitive advantage in the global marketplace.

Understanding Flow Valve Specifications for Efficient Procurement

When it comes to efficient global procurement of flow valves, understanding their

specifications is crucial. Flow valves, which come in a wide array of sizes

and materials, play a vital role in controlling the movement of fluids in various applications. The specification process

often involves considering material compatibility, pressure ratings, and the intended application. For instance, the

ISA-96 series of standards offers a robust framework for understanding the design, operation, and testing

of valve actuators and their accessories, ensuring that procurement professionals are equipped with the necessary knowledge

to make informed decisions.

Moreover, regulations like those surrounding faucets and showerheads underscore the importance of compliance in valve

specifications. Since 1994, the requirement for lavatory and kitchen faucets

to adhere to specific flow rates highlights the need for valves that promote efficiency and sustainability. By focusing

on the technical aspects and standards that govern flow valves, procurement specialists can ensure they are sourcing the

right products that meet industry regulations while also supporting the goal of operational efficiency.

Best Practices for Sourcing Flow Valves in the Global Market

When sourcing flow valves in the global market, understanding best practices is crucial for ensuring efficiency and quality. First and foremost, it’s essential to conduct thorough market research. This involves identifying reputable suppliers and manufacturers in various regions, comparing their product offerings, and evaluating their compliance with international standards. Gathering feedback from existing customers can provide valuable insights into the reliability of these suppliers.

Another key practice is to establish clear communication channels with potential suppliers. Engaging in open dialogue about your specific requirements, pricing expectations, and lead times can help avoid misunderstandings later in the procurement process. Utilizing technology for real-time communication can enhance collaboration and streamline order management. Additionally, consider leveraging global trade platforms to broaden your reach and identify new suppliers who can meet your needs effectively.

Finally, developing long-term relationships with suppliers can lead to more favorable terms and better service quality. By fostering partnerships, businesses can negotiate better pricing models and gain access to new innovations in flow valve technology. Staying proactive in managing supplier relationships will not only ensure a steady supply but also enhance your overall procurement strategy in the competitive global market.

Evaluating Quality Standards and Compliance for Flow Valves Worldwide

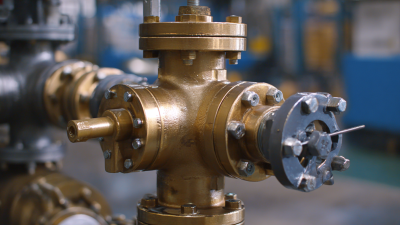

In the realm of global procurement, understanding the quality standards and compliance for flow valves is crucial. Flow valves, essential components in various industrial processes, must meet stringent regulations to ensure safe and efficient operations. With the ongoing emphasis on environmental protection, particularly in maritime contexts, compliance with discharge standards has become a focal point. The recent developments regarding the design and installation of ballast water sample ports signify an important step in verifying compliance with these stringent regulations. Efficiently collecting and testing samples for viable organisms is vital in mitigating the risks associated with invasive species and maintaining ecological balance.

As countries implement strict adherence to these standards, procurement professionals must prioritize flow valves that not only meet, but exceed quality benchmarks. Ensuring that the valves are designed to facilitate easy sampling and examination contributes significantly to overall compliance efforts. It is therefore essential to evaluate suppliers based on their adherence to international regulations, certifications, and the reliability of their products. Investing in high-quality flow valves enhances operational efficiency while simultaneously supporting global sustainability initiatives.

Related Posts

-

Exploring Opportunities for Flow Valves at the Record-Breaking 137th Canton Fair 2025

-

Unveiling New Opportunities for Flow Valves at the Record Breaking Canton Fair 2025

-

Solutions for Optimizing Fluid Dynamics with the Best Flow Valve in Global Industries

-

How to Leverage the 2025 Technological Trends for Best Flow Valve Innovations

-

2025 Tech Trends in Automation Valves: How to Choose the Best Solutions for Your Industry

-

Addressing Common Issues with High Pressure Valve Performance