Finding Quality Suppliers for Best High Temperature Ball Valves: The Ultimate Guide to Ensuring Durability and Performance

In the competitive landscape of industrial valve manufacturing, sourcing high-quality suppliers for High Temperature Ball Valves has become increasingly critical to ensure durability and performance. According to a recent report by MarketsandMarkets, the global industrial valve market is projected to reach $100 billion by 2025, with high-temperature valve applications seeing substantial growth due to the escalating demand in sectors such as oil and gas, chemicals, and power generation.

As industries expand and evolve, the need for reliable valves that can withstand extreme temperatures without compromising functionality becomes paramount. This ultimate guide will delve into strategies for identifying top-tier suppliers, ensuring that your operations benefit from superior High Temperature Ball Valves designed to maintain efficiency and safety in challenging environments.

Understanding the Importance of High Temperature Ball Valves in Industrial Applications

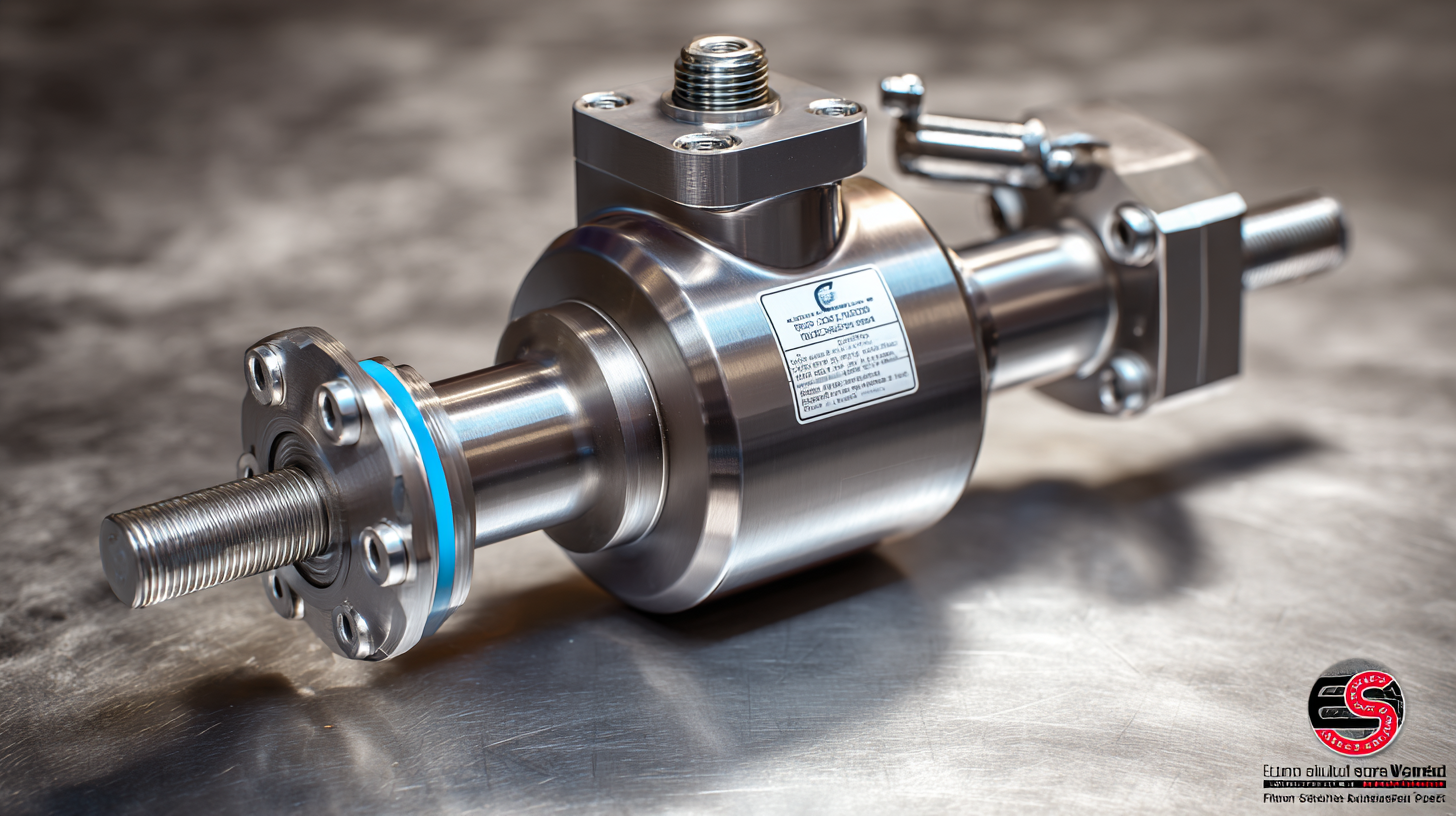

High temperature ball valves play a crucial role in various industrial applications, especially in sectors where extreme temperatures are a common challenge. These valves are essential for controlling the flow of liquids and gases in high-pressure environments, making them indispensable in industries such as oil and gas, chemical processing, and power generation. Their ability to maintain integrity and performance under high temperatures ensures operational safety and efficiency, which in turn supports the overall productivity of industrial systems.

The market for industrial valves, including high temperature ball valves, is experiencing significant growth. Recent projections indicate that the global valve market could reach approximately USD 137.90 billion by 2033, primarily driven by increasing demand in rapidly developing regions such as Asia Pacific. With advancements in technology and digital transformation, manufacturers are increasingly able to develop innovative solutions that enhance the durability and reliability of these critical components. As industries strive to adopt cleaner energy solutions, the focus on high performance valves becomes even more paramount, emphasizing the need for quality suppliers who can meet these evolving demands.

Finding Quality Suppliers for Best High Temperature Ball Valves: The Ultimate Guide to Ensuring Durability and Performance

| Supplier Location | Material Types | Temperature Rating (°C) | Pressure Rating (Bar) | Application Industries |

|---|---|---|---|---|

| USA | Stainless Steel, Carbon Steel | 200 | 50 | Oil & Gas, Chemical Processing |

| Germany | Forged Steel, Alloy | 250 | 60 | Power Generation, HVAC |

| China | Brass, PVC | 180 | 40 | Water Treatment, Food Industry |

| Italy | High Temperature Plastic, Stainless Steel | 300 | 70 | Pharmaceutical, Petrochemical |

| Japan | Heat-Resistant Alloys, Titanium | 350 | 80 | Aerospace, Automotive |

Evaluating Supplier Credentials: Key Factors for Quality Assurance

When searching for quality suppliers of high temperature ball valves, evaluating supplier credentials is crucial for ensuring both durability and performance. Industry reports, such as those from the International Valve Manufacturing Association, indicate that over 70% of valve failures result from inadequate supplier vetting. Therefore, it is essential to assess factors such as certification, manufacturing processes, and material quality when selecting a supplier.

One key aspect to consider is the supplier's compliance with international standards, such as ANSI, API, and ISO certifications. These certifications not only validate the supplier’s commitment to quality but also indicate adherence to best practices in manufacturing and safety. Furthermore, it's beneficial to review customer testimonials and case studies, which can provide insights into a supplier's consistency in delivering high-performance products.

Tips:

- Always verify a supplier’s adherence to regulatory standards and consider visiting their manufacturing facility to gauge their operational capabilities.

- Look for suppliers that offer detailed product specifications and testing results, ensuring transparency in their quality control measures.

- Establish a solid communication channel to discuss any concerns or specific requirements, allowing for a collaborative approach in achieving optimal valve performance.

Sourcing Strategies for Reliable Manufacturers in China

Sourcing quality suppliers for high-temperature ball valves involves strategic engagement with manufacturers, particularly in China, which continues to be a crucial player in global supply chains. According to a recent analysis, China's share of the global manufacturing sector remains significant, particularly in specialized industries such as valves and fittings. In 2023, the trade value between China and major partners reached over $7.5 trillion, indicating the vast potential available for businesses willing to source from reliable suppliers in this region.

To establish a fruitful relationship with manufacturers, businesses should delve into multiple sourcing platforms to find verified suppliers. Utilizing resources like industry-specific networks can help streamline the selection process. A report highlights that using platforms focused on quality sourcing, such as those renowned for connecting with specialized industries, can significantly mitigate risks associated with product reliability and performance. Moreover, amid rising tariffs and trade tensions, companies must remain aware of the evolving economic landscape, as these factors could affect sourcing strategies and supplier engagements. Adopting a thoughtful approach not only ensures quality but also fosters long-term partnerships in an increasingly complex market environment.

Quality Control Measures to Ensure Product Durability and Performance

When sourcing high temperature ball valves, quality control measures play a pivotal role in ensuring product durability and performance. Various standards and testing protocols can help manufacturers maintain consistency in their products. Implementing rigorous inspection processes at different stages of production—from raw material selection to final assembly—can significantly reduce defects and enhance reliability.

One critical aspect of quality control is material integrity. High temperature applications demand materials that can withstand extreme conditions without compromising structural integrity. Regular testing for hardness, tensile strength, and resistance to thermal fatigue is essential. Additionally, organizations should consider adopting International Organization for Standardization (ISO) standards for quality management to ensure a systematic approach towards performance evaluation.

Moreover, investing in advanced technology for testing and monitoring can further bolster quality assurance. Non-destructive testing (NDT) methods, such as ultrasonic or radiographic testing, enable manufacturers to detect flaws without damaging the valves. By combining these proactive measures, companies can not only meet but exceed customer expectations, fostering trust and enhancing their reputation in the market for high temperature ball valves.

Trends in High Temperature Ball Valve Technology and Market Demand

In the ever-evolving landscape of industrial applications, high temperature ball valves are gaining increased attention for their durability and performance capabilities. Recent market trends highlight a shift towards advanced materials and innovative designs that can withstand extreme conditions. This change is driven by the growing demand in sectors such as energy, chemical processing, and manufacturing, where reliable and efficient control over fluids at high temperatures is crucial.

**Tip:** When searching for high temperature ball valves, consider suppliers who utilize cutting-edge technologies like forged steel bodies and specially designed sealing materials. These features can significantly enhance the lifespan and operational efficiency of the valves.

Furthermore, the rise of automation and smart technologies is influencing the high temperature ball valve market, with a focus on integrating IoT capabilities for real-time monitoring and control. As companies seek to optimize their processes and reduce downtime, the push for valves equipped with advanced sensors and data analytics will continue to grow.

**Tip:** Always verify that potential suppliers are aligned with recent technological advancements and can provide custom solutions tailored to your specific operational needs. This ensures that you not only meet current demands but also future-proof your operations against evolving industry standards.

High Temperature Ball Valve Market Trends

This chart illustrates the projected market demand for high temperature ball valves across different temperature ranges. The data reflects anticipated growth in specific temperature segments, emphasizing the increasing importance of durability and performance in the industry.