The Future of Ball Valve Control Valve Innovations in Industrial Applications

In the realm of industrial applications, the emergence of advanced technologies continues to reshape the landscape of control systems. Among these innovations, Ball Valve Control Valves are gaining significant attention for their efficiency and reliability. According to a recent report by MarketsandMarkets, the global control valve market is projected to reach USD 9.6 billion by 2026, growing at a CAGR of 6.8%. This surge is fueled by the increasing demand for automation in various sectors, including oil and gas, water and wastewater, and power generation.

Ball Valve Control Valves, known for their precision in flow control and minimal pressure drop, play a pivotal role in enhancing operational efficiencies and reducing energy consumption. As industries strive for greater sustainability and performance, understanding the future innovations of Ball Valve Control Valves becomes essential for staying competitive in an ever-evolving market.

Key Advances in Ball Valve Technology for Enhanced Performance

The realm of ball valve technology is witnessing remarkable innovations aimed at enhancing performance in industrial applications. One of the key advances is the integration of smart technologies into valve systems. These smart ball valves are equipped with electronic actuators that allow for real-time data collection and remote monitoring. This not only enhances operational efficiency but also facilitates predictive maintenance, minimizing downtime and reducing operational costs.

Additionally, advancements in materials have significantly improved the durability and performance of ball valves. Newly developed composites and alloys offer greater resistance to corrosion and wear, thus extending the lifespan of valves under extreme operating conditions. Moreover, innovation in sealing technologies has led to lower leakage rates and improved reliability, making modern ball valves safer and more effective for critical applications in industries such as oil and gas, water treatment, and chemical processing. These advances are setting new standards in performance and reliability, pushing the boundaries of what is possible in fluid control systems.

The Future of Ball Valve Control Valve Innovations in Industrial Applications - Key Advances in Ball Valve Technology for Enhanced Performance

| Technology | Description | Advantages | Application Areas |

|---|---|---|---|

| Smart Control Systems | Integration of IoT-based controllers for real-time monitoring and control. | Increased efficiency, predictive maintenance, enhanced data analytics. | Oil & Gas, Water Treatment, Chemical Processing. |

| Advanced Materials | Using composite materials for improved durability and corrosion resistance. | Longer lifespan, reduced maintenance costs, better performance in harsh environments. | Marine, Aerospace, Petrochemical. |

| Electromagnetic Actuators | Actuators powered by electromagnetic signals to enhance precision and speed. | Fast response times, increased accuracy, reliable operation. | HVAC, Food & Beverage, Pharmaceuticals. |

| Self-Adjusting Valves | Valves that automatically adjust to varying pressure conditions. | Enhanced safety, consistent flow rates, lower energy usage. | Mining, Waste Management, Energy Sector. |

| Leak Detection Systems | Integration of sensors to detect leaks and prevent failures. | Improved safety, reduced environmental impact, lower operational risks. | Chemical Plants, Power Generation, Water Supply. |

Integration of Smart Technologies in Control Valve Systems

The integration of smart technologies in control valve systems marks a significant evolution in industrial applications, enhancing both efficiency and reliability. With the advent of the Industrial Internet of Things (IIoT), control valves can now be monitored and managed remotely, providing operators with real-time data on performance and operational conditions. This immediate access to information allows for proactive maintenance, reducing the risk of unexpected downtimes and ensuring optimal process control.

Additionally, smart control valves are increasingly equipped with advanced features such as adaptive learning algorithms and predictive analytics. These capabilities enable the systems to not only respond to current process demands but also anticipate future requirements based on historical data. This level of intelligence facilitates improved decision-making and enhances overall system performance by minimizing energy consumption and optimizing fluid dynamics. As industries continue to push for greater automation and efficiency, the integration of smart technologies in control valve systems becomes not just a trend, but a necessity for staying competitive in a rapidly changing landscape.

Sustainable Practices in Valve Manufacturing for Future Applications

As industries evolve, there is an increasing demand for sustainable practices in valve manufacturing, particularly for ball and control valves used in various industrial applications. The shift towards eco-friendly methods is not merely a trend but a necessary adaptation to meet regulatory standards and consumer expectations. Manufacturers are now focusing on utilizing recyclable materials, reducing waste during production, and implementing energy-efficient processes. By adopting these sustainable methods, companies not only contribute to environmental conservation but also enhance their brand reputation, appealing to a market that is increasingly prioritizing sustainability.

Furthermore, innovations in valve design are closely linked to sustainability efforts. Advanced manufacturing techniques such as 3D printing and automation are enabling more precise production with less material waste. These technologies allow for the creation of lightweight, durable valves that have a lower environmental impact throughout their lifecycle. Additionally, manufacturers are investing in research to produce valves that promote efficiency in fluid control systems, reducing energy consumption and lowering emissions in industrial processes. This holistic approach ensures that as we look to the future, valve manufacturing can achieve the dual goals of efficiency and sustainability, paving the way for greener industrial applications.

Improving Efficiency and Safety in Industrial Processes with Modern Valves

The industrial sector is witnessing a transformative shift in valve technology, with modern ball valves and control valves playing pivotal roles in enhancing efficiency and safety. According to a report by Research and Markets, the global valve market is expected to reach $119.4 billion by 2025, growing at a CAGR of 8.5%. This growth is partially driven by innovations such as smart actuators and IoT integration, which allow for real-time monitoring and control of fluid dynamics in industrial processes. These advancements not only optimize the performance of processes but also aid in predictive maintenance, reducing downtime significantly.

Moreover, safety considerations are paramount in industrial applications, where malfunctions can lead to catastrophic consequences. A study published in the Journal of Loss Prevention in the Process Industries reveals that the implementation of advanced valve technologies can mitigate risks by providing more reliable shut-off capabilities and enhancing system integrity. For instance, the adoption of automated valves equipped with sensors can detect leaks or pressure changes, triggering immediate corrective actions. This proactive approach can reduce the likelihood of accidents and bolster compliance with stringent safety regulations, ultimately fostering a safer working environment.

Emerging Trends in Valve Automation and Control Systems

The landscape of valve automation and control systems is evolving rapidly, with emerging trends that are significantly enhancing the performance and efficiency of industrial applications. One noteworthy trend is the integration of IoT (Internet of Things) technology into valve systems, allowing for real-time monitoring and data analysis. This connectivity enables operators to make informed decisions based on live data, leading to improved maintenance schedules and reduced downtime. As industries increasingly embrace smart manufacturing, the ability to remotely control and optimize valve operations is becoming essential.

Another innovation shaping the future of valve control is the implementation of advanced artificial intelligence algorithms. AI-driven systems can predict potential failures and optimize operational parameters to enhance energy efficiency. Coupled with machine learning capabilities, these systems can learn from historical data to make proactive adjustments, thus ensuring seamless processes in challenging industrial environments. As these technologies mature, they are set to redefine traditional methods of valve operation, paving the way for more sustainable and cost-effective industrial practices.

Related Posts

-

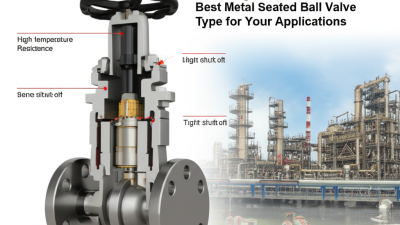

Understanding the Advantages of the Best Metal Seated Ball Valve Type for Your Applications

-

Unveiling New Opportunities for Flow Valves at the Record Breaking Canton Fair 2025

-

5 Essential Pressure Control Valve Facts Every Engineer Should Know

-

Real World Applications of Best Ball Valves and Solutions to Common Challenges

-

Unmatched Quality from China Top Factories Leading the World Trust in Best Flow Valves

-

Innovative Solutions for Enhancing Efficiency in Valve Control Valve Applications