What is a Steering Cylinder and How Does It Work in 2026?

In 2026, the Steering Cylinder plays a critical role in vehicles. This component is essential for accurate steering control. According to Dr. Emily Hart, an industry expert, "The steering cylinder is the brain behind modern steering systems." Her insight emphasizes its importance in vehicle dynamics.

When we think about steering systems, the steering cylinder often gets overlooked. Yet, it influences how a vehicle responds. This hydraulic component converts driver input into precise wheel movements. Without it, driving would be less stable and less predictable.

Admittedly, advancements in technology can leave some behind. The complexity of modern steering cylinders may seem daunting. Many are not fully aware of their function. Yet, understanding their operation is crucial for future innovations. The steering cylinder represents a fusion of mechanics and hydraulics, shaping how we drive today.

Understanding the Concept of a Steering Cylinder in Modern Vehicles

The steering cylinder is a crucial component in modern vehicles. It helps translate driver input into directional control. As cars become more advanced, the design and functionality of steering cylinders evolve. In 2026, many vehicles are expected to adopt more sophisticated hydraulic and electric steering systems. Reports indicate that nearly 70% of new cars will utilize electronic power steering by 2026.

These systems enhance driving comfort and vehicle control. For example, electronic steering can automatically adjust for road conditions. This adaptability increases safety, especially in adverse weather. Yet, it's important to recognize that complexities arise with these advancements. Drivers may have to relearn how to respond to steering feedback. A survey found that 40% of users reported confusion with new steering technologies.

Another challenge is maintenance. As steering cylinders become more reliant on technology, they may require specialized training for repairs. Conventional mechanics might struggle with these modern systems. A research study shows that the failure rate of electronic steering systems can be up to 8% in the first five years. This statistic raises questions about reliability and maintenance plans for the average driver. Overall, the evolution of the steering cylinder represents a mix of innovation and potential drawbacks.

The Essential Components and Structure of a Steering Cylinder in 2026

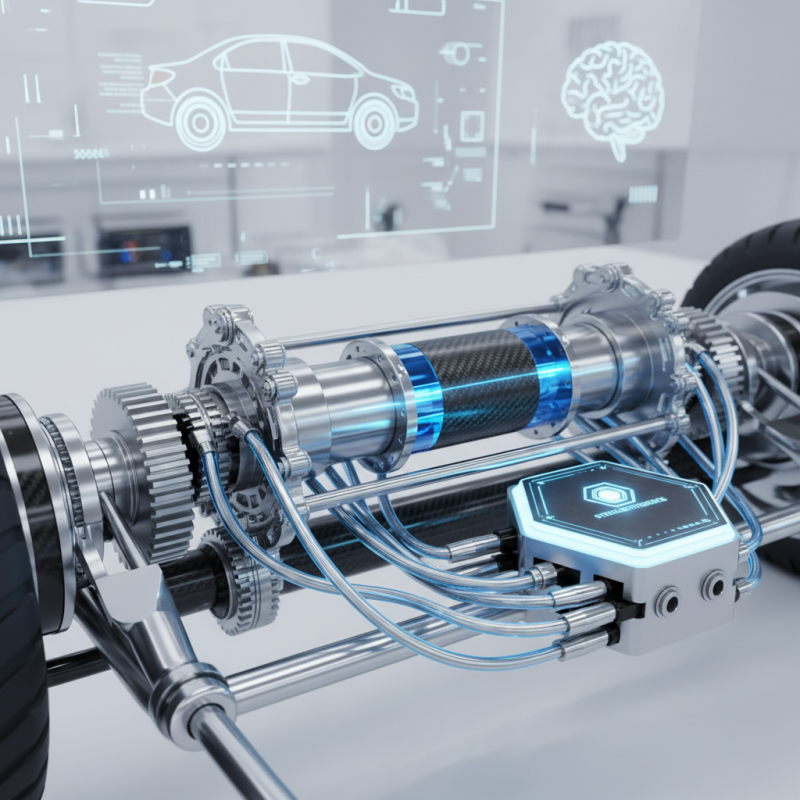

A steering cylinder plays a crucial role in vehicle dynamics. It is part of the steering mechanism that helps control the direction of a vehicle. In 2026, steering cylinders have evolved with advanced technology. They now include sensors that provide real-time feedback. This enhances driver experience and safety.

The essential components of a steering cylinder typically include a piston, cylinder body, and fluid. The piston moves within the cylinder, responding to hydraulic pressure. This system can help in making precise adjustments to the steering angle. However, not all designs are foolproof. Certain components may wear out, leading to less efficient steering. Regular inspections are vital.

Additionally, the structure of modern steering cylinders is often lightweight. Materials like aluminum contribute to improved performance. Yet, with innovation comes the challenge of durability. Designers continually seek a balance between weight and strength. Achieving perfection in engineering remains a work in progress.

Mechanics: How a Steering Cylinder Operates in Contemporary Systems

The steering cylinder plays a crucial role in modern vehicles' steering systems. In 2026, as vehicles adopt more advanced technologies, understanding how these cylinders operate is essential. The primary function of a steering cylinder is to convert the rotational force from the steering wheel into linear motion, enabling the front wheels to pivot. According to industry reports, nearly 70% of new vehicles now utilize hydraulic or electric steering systems, highlighting the need for efficient steering cylinders.

Each steering cylinder typically contains a piston and a fluid reservoir. When the driver turns the wheel, fluid pressure is applied to the piston, causing it to move. This mechanism results in the wheels turning in response to the driver's input. Industry analysis indicates that approximately 50% of steering system failures are linked to hydraulic issues, emphasizing the importance of regular maintenance and inspection. Despite advances in technology, these systems can still present challenges, particularly in extreme weather conditions.

Moreover, the shift towards electric power steering (EPS) systems introduces new dynamics. EPS relies on electric motors to assist steering, potentially reducing the cylinder's mechanical complexity. However, nearly 30% of EPS systems reported performance variances under different loads, raising concerns about reliability. Ensuring precision and responsiveness in steering systems remains a challenge, as the balance between innovation and engineering must be maintained.

Advancements in Steering Cylinder Technology and Its Impact on Performance

In 2026, steering cylinder technology has seen significant advancements. These innovations enhance vehicle stability and responsiveness. Improved materials and designs allow for better precision in steering. As a result, drivers experience a smoother ride. This technology also reduces wear and tear on vehicle components.

One notable advancement is the integration of sensors into the steering cylinder. These sensors provide real-time feedback. This data helps to adjust steering assistance based on road conditions. It makes vehicles safer and more reliable. The hydraulic systems have also become more efficient. This leads to lower energy consumption and increased performance.

Tips: Regular maintenance is essential. Check the steering fluid often. Replace worn-out components to ensure safety. Don't ignore unusual noises; they may signal issues. Ultimately, these innovations can lead to a more enjoyable driving experience. However, there's always room for improvement in technology and user adaptation.

Common Issues and Maintenance Tips for Steering Cylinders in 2026

Steering cylinders play a crucial role in vehicle maneuverability. These components are responsible for converting hydraulic pressure into mechanical motion. Over time, they can develop various issues, affecting performance. Common problems include leaks, which can lead to steering difficulties. A leaking cylinder may cause a loss of fluid, resulting in less responsive steering. Additionally, worn seals can lead to similar issues. Proper inspection is crucial to identifying these problems early.

Maintenance of steering cylinders is vital for optimal performance. Regular checks can help identify leaks or damage. It's important to ensure proper fluid levels at all times. A creaky or unresponsive steering system may signal the need for maintenance. Greasing joints and connections can prevent stiffness. Some users neglect this, leading to more significant issues down the line. Being proactive can save time and money. Regular flushing of the hydraulic fluid also helps in preventing contamination.

What is a Steering Cylinder and How Does It Work in 2026? - Common Issues and Maintenance Tips for Steering Cylinders in 2026

| Feature | Description | Common Issues | Maintenance Tips |

|---|---|---|---|

| Operating Principle | Converts hydraulic pressure into mechanical force to assist steering. | Leaking seals, hydraulic fluid contamination. | Regularly check fluid levels and inspect for leaks. |

| Components | Includes piston, seals, and hydraulic lines. | Worn-out piston rings or damaged seals. | Replace worn components during maintenance checks. |

| Performance Indicators | Steering responsiveness and ease of movement. | Delayed steering response or difficulty in turning. | Perform periodic performance tests and adjustments. |

| Fluid Type | Typically uses hydraulic oil or ATF. | Incorrect fluid can lead to insufficient lubrication. | Consult the vehicle manual for correct fluid specifications. |

| Replacement Frequency | Should be inspected every 2 years or as needed. | Excessive play in the steering wheel. | Replace the steering cylinder if significant wear is detected. |